Introduction:

In the year 1960, the process of Orbital welding was developed and used for the first time to take care of the issues related to fuel and hydraulic fluid leakages by Roderick Rohrberg, while working for North American Aviation on the X-15 rocket research plane. In the 1980s after advancements in portability, control systems and power supplies, it was intended that the machines used for orbital welding could be carried between various construction sites. This increased the use of this process more and more as we know it today.

Let’s know about the process, advantages – disadvantages and where, when and how to use Orbital Welding.

What are Orbital Welding and its process?

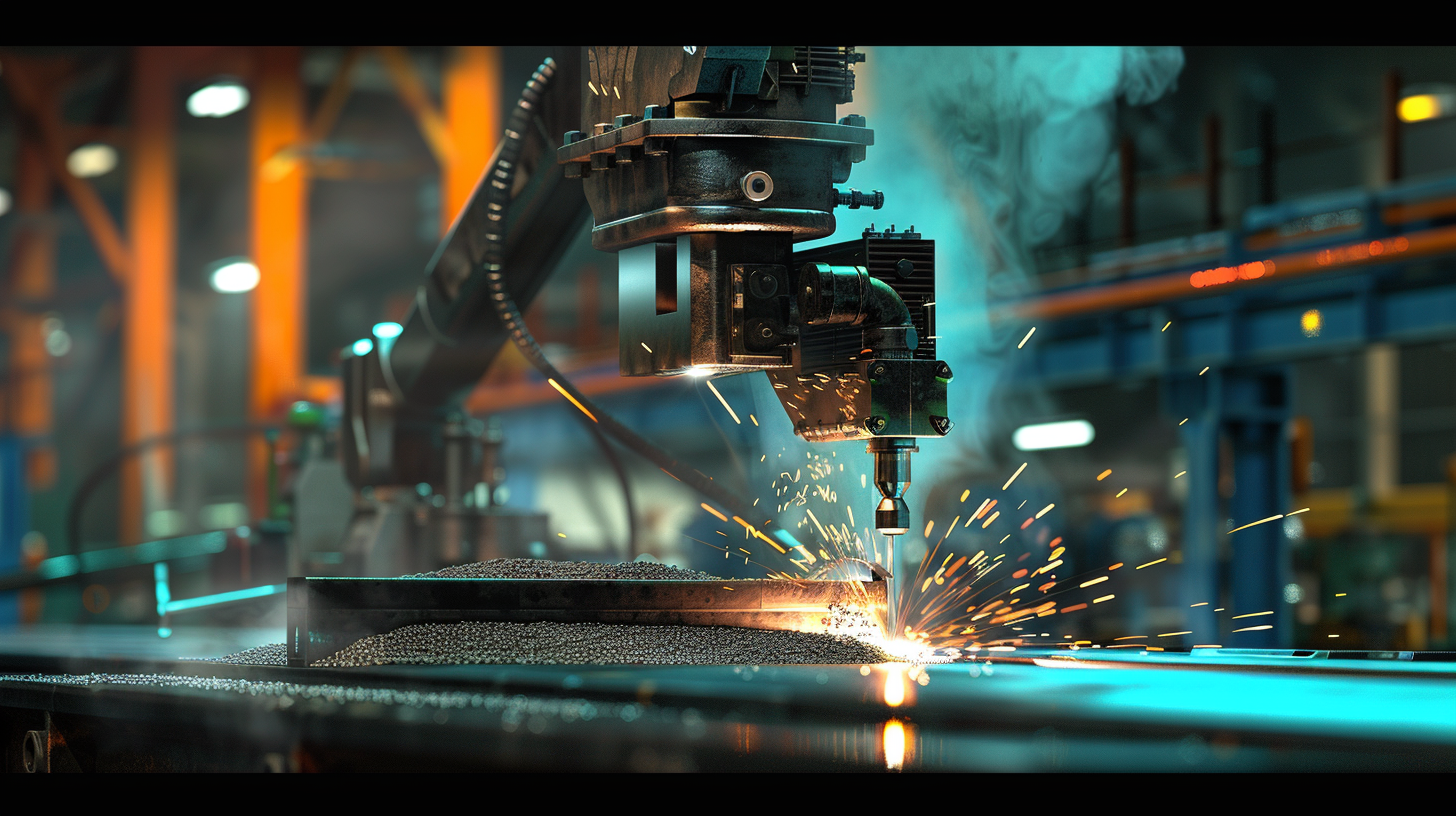

As the name signifies, Orbital welding is a process in which a Welding arc is rotated 360° through an orbit to join two metals or any workpiece together which is in a stagnant position. In the process of double welding, it is rotated 180°.

There are two processes which utilize Orbital Welding majorly –

Tube-to-Tubesheet joining

Pipe-to-pipe joining (or tube-to-tube joining)

It was originally made to solve the manual/operator errors in TIG Welding. In Orbital Welding, there is comparatively less interference from a welding operator. As it was developed to create superior-quality welds with the use of computers. And it achieves par excellent results, especially in the cases of tubes and pipes.

Process of using Orbital Welding:

Orbital welding uses a specially designed machine. This machine cuffs the pipe or tube to be welded and the welding arc rotates around this job piece in an orbit to create welds. This process can be repeated immensely because the settings of welding parameters, which are set by a microprocessor, can be stored and reused N number of times.

This process can be fulfilled using two different methods that have their own uses and benefits:

-Consumable Electrode: It uses power from the wire feeder which provides metal to the arc

-Non-Consumable Electrode: It uses encased electrodes that are in-built into the orbital welding system and Tungsten Inert Gas.

What is required to make an Orbital Welding Equipment?

Most important is the integrated computer control system and a power supply to work with it, different sizes of orbital welding heads (depending upon the job piece) and a wire feeding system. Additionally, Air/Water coolant can be required for some materials or a certain sized part.

When to use Orbital Welding?

- When the aim is to accomplish high-quality welds in the positions such as down-hand or overhead then we use orbital welding as it’s an automated process. High quality and maximum safety are difficult to achieve when it comes to these certain positions when welding is attempted manually (which results in faulty welds). A welder’s job would only be to supervise and adjust the process as per requirements.

- Pharmaceuticals as well as semiconductor industries require leakproof and high-level integrity. These industries consider orbital welding as their standard joining method for their highly pure gas and liquid systems.

- Steadier outside diameters are created in tubing production that is preferable fit in the weld head of machines in orbital welding. Therefore it is more prevalent to use orbital welding for tubes rather than for pipes.

- Apart from these, orbital welding can be considered an ideal option to use for the following:

- Projects that have higher specifications or a higher volume of job

- Where consistency and definitiveness are given high priorities

- Places with environments harsh enough to approach manually like – narrow work space, presence of fatal or dangerous fumes or radiation, low visibility

- Or even if the skilled welders are fewer in number or are rarely available

What Industries/processes use Orbital Welding?

Orbital Welding has been adopted by many industries and in many different kinds of settings because this process creates joins that are dependable and smooth. It has been proven highly adaptable for welds that are otherwise much more complex. Some of the industries that use Orbital welding are:

- Aerospace Industries: A certain amount of pressure is created by flying at certain altitudes. Welds created by orbital welding remain flawless and smooth while withstanding the pressure. Orbital Welding has been used for decades in making parts in the aerospace industry.

- Beverages, Food and Dairy Industries: Applications used in these industries have to maintain their sanitation and safety standards. This requires high-quality welds and a lot of them require smooth surfaces and a good amount of insertion. These results can be achieved by Orbital Welding.

- Semiconductors: Orbital welding prevents the formation of contaminants. So it is used for semiconductors to provide smooth surfaces even to the batches of welding.

Conclusion:

So to conclude Orbital Welding can be the solution to create high-quality welds in many difficult or risky environments. The welds can be considered exceptionally dependable and can be repeated numerous times even with rare and unusual materials, metals, and parts having small diameters or thick and large walls. In some cases, Orbital Welding can be the only way to weld and has proved to give efficient results.

We would be glad to have feedback from our readers. It helps us to give better output every time when we get connected to our viewers. Keep viewing and stay connected with us.