Home » Training

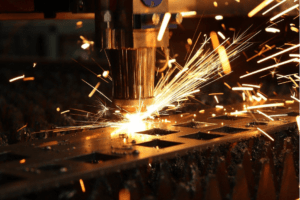

We impart Industrial training which includes Fabrication trade, Safety, and Simulator based training for Welder & Paint applicators. We specialize in customizing onsite training and turnkey training centre management solutions.

Trade tests and skill validation is an important aspects of the assessment of individual skills. We conduct trade tests for trades like Welding and Painting which have the provision of ensuring the adherence to specific standards and codes in order to qualify a person for their respective trade. Trade tests for other vocational trades can be done on a pre-decided matrix jointly curated by the client and our team, pertaining to the requirements. In recent times, our simulator-based trade test and skill assessment have gained immense popularity. It provides an unbiased and accurate platform for skill assessment. We can easily provide a trade test facility in our centre or at the site.

Our training service category includes :

Course at a glance –

On Site Welding Training Simulator Support by Technology Partner : Skillveri

Course at a glance –

Course at a glance – Arc welding & brazing

Courses at a glance – Resistance welding

Courses at a glance – Fabrication

Approach :

Our prime motive for training center management is to provide end to end support and a well curated training plan for the trainee on site. We offer our expertise and ensure seamless execution of the trainees and create a solid foundation before the execution of the center. Our team adheres to all the protocols and guidelines involved in the training process as per industry standards.

Trade test is an important aspect for assessing competency of trainees and effectiveness of training delivered. Many standards & codes are available for fair assessment of trade skills. We specialize in conducting trade tests as per applicable standards and codes. Customized skill assessment matrix is another tool for trade skill assessment. Our domain experts work jointly with the client to make a customized assessment criteria and then conduct a trade test based on the assessment matrix. All aspects of our modern life as we know it, cannot function efficiently without a digital presence and utility of such resources. We are proud to provide simulator based trade tests as well, for welding & painting applicators.