Maintenance is an important aspect concerning any machine. A common example can be your vehicle that needs services and maintenance at regular intervals for smooth running. Similar is the case for machines used for industrial purposes. They go through various types of pressure and tensity, especially industrial ovens, which take a lot of heat. To maintain the quality, increase the life, and reduce the recurrence of shutting down ovens, it’s important to have a maintenance schedule. For today’s article, let’s briefly get the gist of electrode drying ovens and dive right into the various ways of maintaining them.

What are Electrode Drying Ovens?

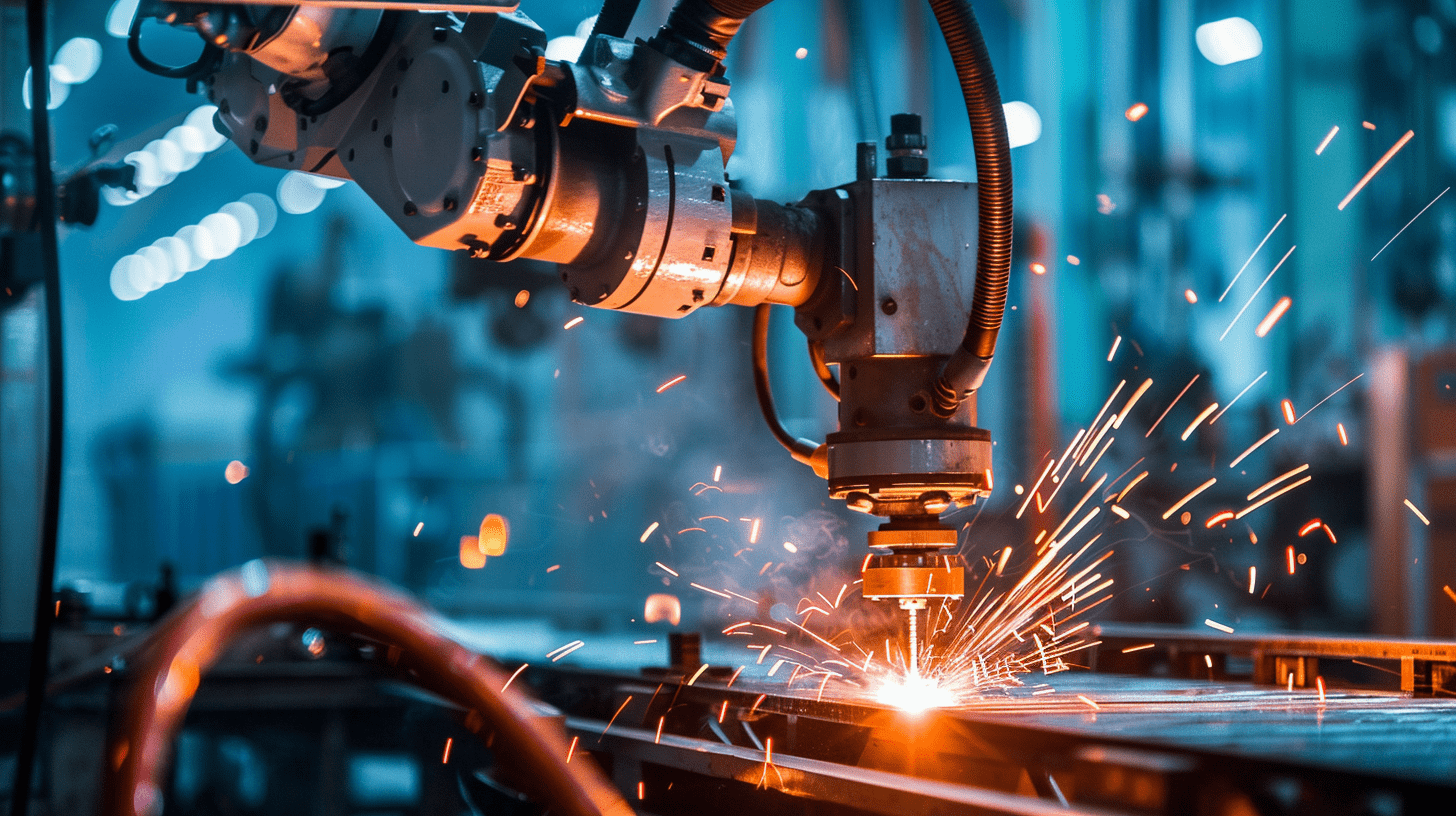

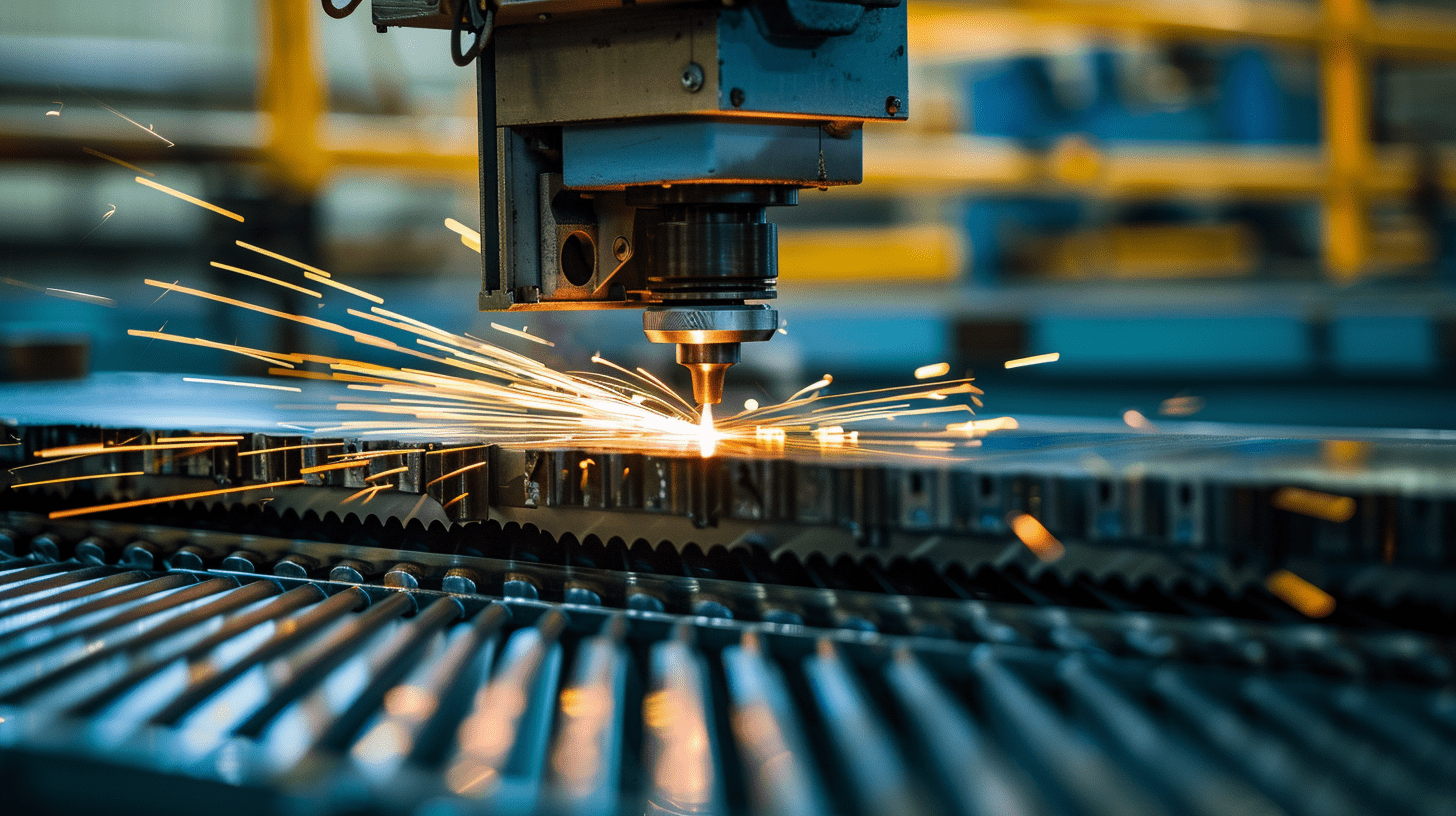

Welding electrodes if not stored properly can start absorbing moisture. This can result in porosity in the weld deposit. To avoid such problems, Electrode drying ovens were designed. Moreover to recover the quality of welding electrodes these ovens serve as redrying equipment as well. As a result, stick electrodes are fresh and ready for welding.

Even though there are different types of ovens and they are used as per the requirement of those industries, the following are some of the common yet best maintenance practices to follow for your ovens:

Maintenance of Blower Motor: Being one of the most important components of ovens, the blower motor (depending upon its type) requires proper lubrication. It’s essential to refer to the owner’s manual while oiling it. There are lubrication points in the housing of the motor (in front and back). Oil must be applied to them. A motor can become unstable if any foreign material or loose blanket insulation from the oven gets caught in the blower. To keep these vent openings clean an air jet or vacuuming can be used. If kept dirt and debris-free, the risk of the oven stopping prematurely can be reduced.

- Correct Power Usage:

Providing a steady power supply is a must. Overload or reduced supply may result in poor performance or failure of solenoid valves and relays. With the help of buck-boost transformers, steady power can be supplied.

- Checking Heating Elements:

One of the most important steps in maintenance or if the performance of the oven dips or it takes more than usual for it to heat up – check the heating elements. As burnt out or bad elements can lead to a reduction in performance. Replacement depends completely on the type of oven used. The tubular elements can be examined visibly by pulling the heater. Clean them (to avoid built-up) if found dirty and foreign contaminants to be removed. To avoid grounding or shorting, check if any are detached or crooked and not touching any other oven system or alloy hearths. Oxidation and arcing can lead to terminal burnout which can be caused due to loose connections. To avoid this check if all the element terminals are tight by removing the back plate of the heater.

Before checking or replacing any part it’s very important to turn the power off to the control system. Noncompliance can lead to severe personal injuries or death.

- Checking Oven Location / Airflow and checking Thermocouples:

The placement/location of the oven should be such that there is Continuous airflow around the blower motor. The air outlets or inlets if restricted can cause untimely failure of the element.

If there is a sensor break that causes the oven to shut then there is a fault in the oven temperature sensor or its wiring. In this situation – a broken extension lead or broken/open thermocouple needs to be corrected. It is advised to replace the thermocouple with the same type as used previously. While replacing it, make sure to check its polarity, and bend it to match its original structure. The heating process can be continued if the temperature reading and the temperature of the oven rise.

- Additional maintenance / Inspections / Check-ups:

To make sure that all the locking devices work properly, checking of slide assemblies and mounting needs to be done on the regular basis.

Periodical inspections of oven doors and other port inserts too should be done to check whether there are any missing sections, breaks, or torn gaskets. Torn gaskets, if any, can be the cause if you identify that the heat is escaping from the oven.

Other parts like fuses, fan belts, and breakers need to be replaced periodically as these parts also play a key role in the appropriate functioning of most ovens.

Usually, the manual received with the equipment defines which tasks need to be performed by the owner and certain tasks such as cleaning, inspection, and/or adjustments to be made in combustion systems and gas burners, need the assistance of qualified and trained professionals.

Conclusion

Every Oven is different and it’s advisable to leave the maintenance in the hands of the experts. A checklist is a must for every oven owner.

We hope these tips help you understand various ways to check and maintain the quality and increase the life of industrial ovens. We would be glad to have feedback from our readers. It helps us to give better output every time, when we get connected to our viewers. Keep viewing, keep learning and stay connected with us.