Introduction

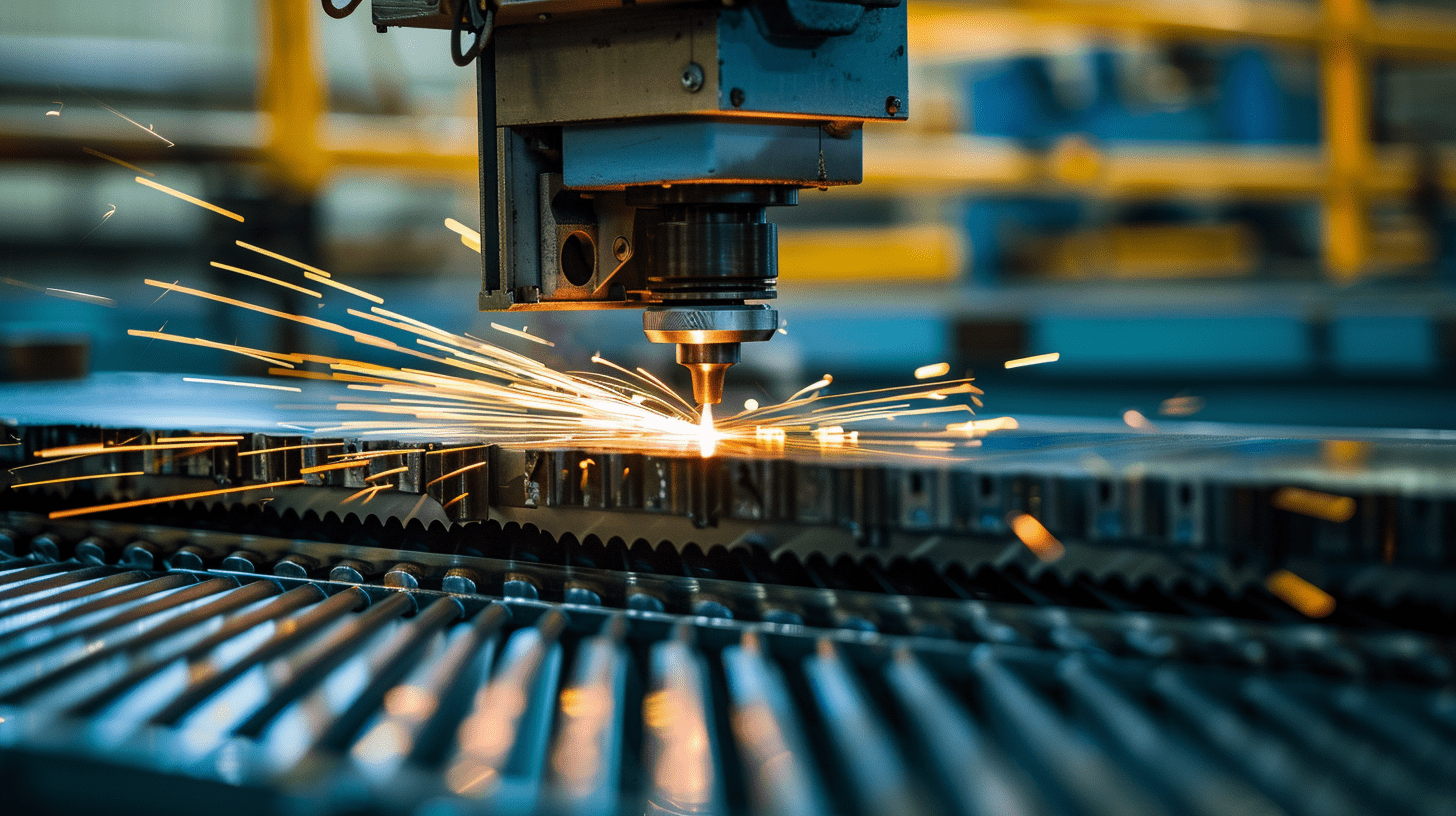

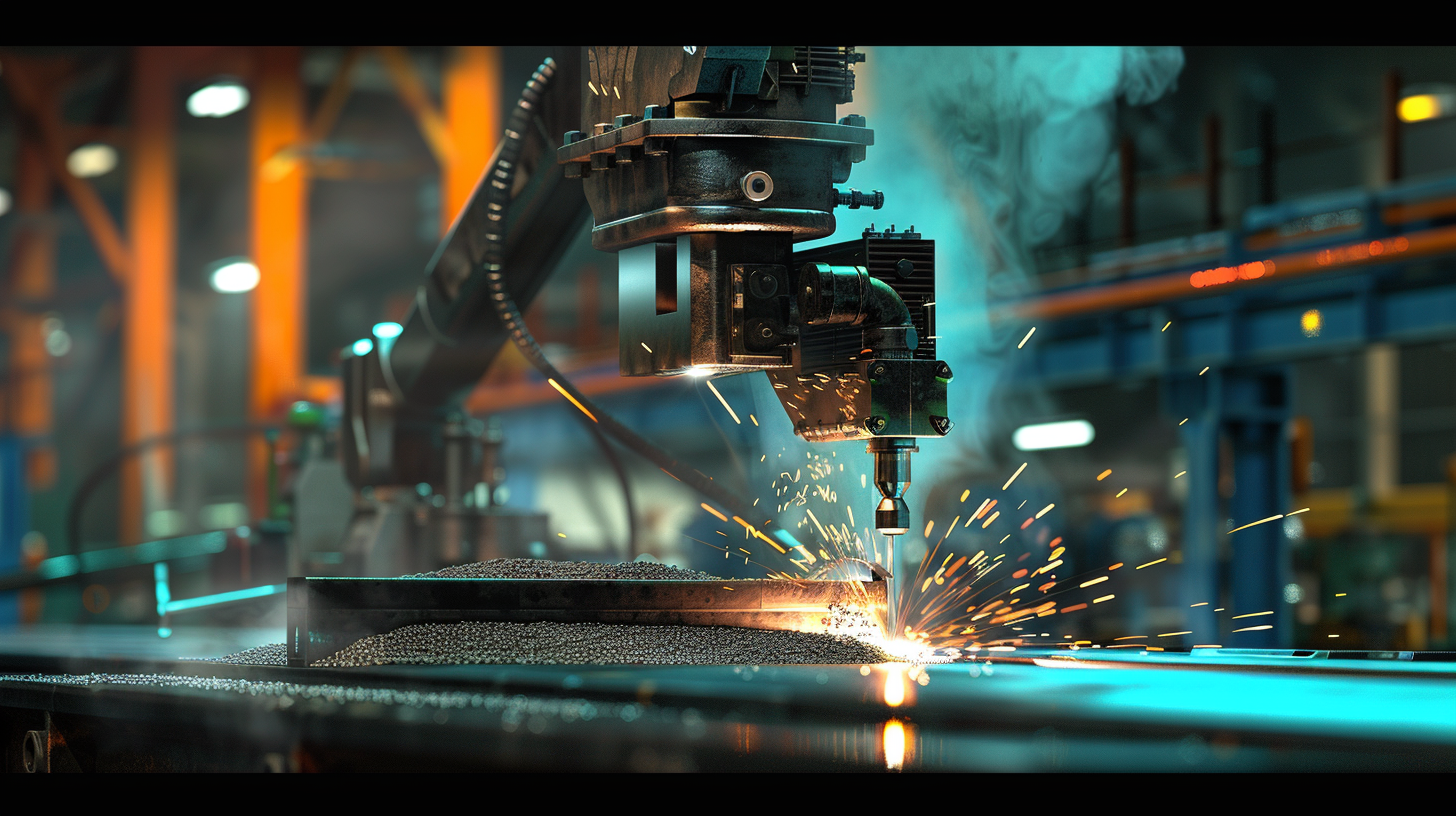

An air plasma cutting machine is used to cut conductive materials such as steel, copper and aluminium through electricity using a high-velocity jet of ionized gas or plasma. The process of creating plasma arcs start with passing air or mixture of various gases through a nozzle which creates an enormous hot plasma. This hot plasma then melts the metal. The demand of this technology is increasing rapidly in the metal working industries as this process offers various advantages such as faster cutting, less waste reduction and higher precision which is difficult to get through traditional cutting methods.

Components of An Air Plasma Cutting Machine

Following are the important components of an air plasma cutting machine:

- Plasma Torch: Plasma torch is a part that helps in creating the plasma arc. This plasma arc is used for cutting the metals.

- Power Supply: Power Supply is used to provide the required amount of electricity to create a plasma arc.

- Gases: Air or mixture of other gases is required to give a formation to the arc. It is also used to cold down the torch.

- Control Systems: Control systems are used to control the cutting speed, maintaining stability of the arc and other parameters.

Demand of An Air Plasma Cutting Machine

Air Plasma Cutting Machine is a highly demanded machine in today’s fast paced world. Some of the key industries that uses this machine are as follows:

- Automation: The demand for air plasma cutting machines in the automation industry is due to its advanced cutting technology. Air plasma cutting machines are installed in the automatic systems and allow production cycles to complete faster. It also improves the operational efficiency of these systems. Automated plasma cutting systems deliver high precision and do not require much of the human force. This reduces the chances of errors and need for manual labour.

- Metal and Automotive Industries: Metal Industry can be considered one of the largest consumers of plasma cutting machines. Plasma cutters are used to cut metals that are used in the construction of various machineries, their components and some consumable products as well. Similarly, the automotive industry uses plasma cutters in the making of body panels, exhaust systems and frames. There has been a significant rise in the demand of customized metal parts and vehicles of light weight in the automotive industry. As plasma cutting machines offer high precision, it is effective for both development of prototypes and mass production.

- Aerospace and Defence: Demand for plasma cutting machines is also increasing in the aerospace industry due to the need for high-quality cuts in titanium, aluminium, etc. Those materials are used in manufacturing of aircrafts. Plasma cutting machines offer clean cuts and display high tolerance which makes it an ideal choice for the automotive industry. In the defence industry, plasma cutting machines are used in the production of military equipment such as military vehicles, defence systems and weapons.

Advantages of An Air Plasma Cutting Machine

Plasma cutting machines are very useful and highly demanded tool in various sectors due to their strong properties. Some of the advantages of plasma cutting machines are as follows:

- Cost-Effective and Speed: Cost-effectiveness is one of the key advantages of plasma cutting machines. These machines are cheaper as compared to laser machines or waterjet cutting machines, which makes them an ideal choice for small and medium sized manufacturers. Despite being cheap, plasma cutting machines have high cutting speed and require less maintenance. This reduces the operational cost of the production to some extent. As compared to traditional methods, plasma cutting machines have a fast-cutting speed and allows the manufacturers to produce a greater number of parts.

- Versatility: Plasma cutting machines can cut through various metals such as steel, copper, stainless steel, brass, copper, aluminium and many more offering a range of versatility. It becomes a prime choice of industries that require cutting of different types of metals.

- Reduction of Material Waste: Plasma cutting machines also reduce material waste due to their precision. The plasma arcs deliver clean cuts and minimize the need of rework. It also reduces the scrap and waste during the cutting process. It helps the companies in saving material costs and accomplishing sustainability goals.

Recent Advancements of Plasma Cutting Technologies

There have been a lot of new developments in plasma cutting technology in recent times. The new plasma cutting machines consist of advanced features for example automatic height control. This feature helps in adjusting the distance between the cutting head and material and guarantees consistency in quality of cutting. High Definition (HD) plasma is also used to get more precision in cuts and fulfilling demands of the application. Many manufacturers are ingesting digital control systems into the cutting machines which provides thema whole real-time report about the cutting parameters.

Various eco-friendly measures have also been taken in those recent advancements by keeping sustainable practices in mind. The recently designed models require less power consumption making it more environment friendly. Various alternatives are being researched to replace traditional practice of compressing air into the plasma machine. This helps in adjusting the settings for improvement of the performance and reduction in energy consumption.

Take Away

This is the brief explanation about the Air plasma cutting machine, its properties and demands and recent innovations in technology. We hope this information will be effective for you. Please let us know through your valuable feedback and the suggestion in the drop box.