Introduction

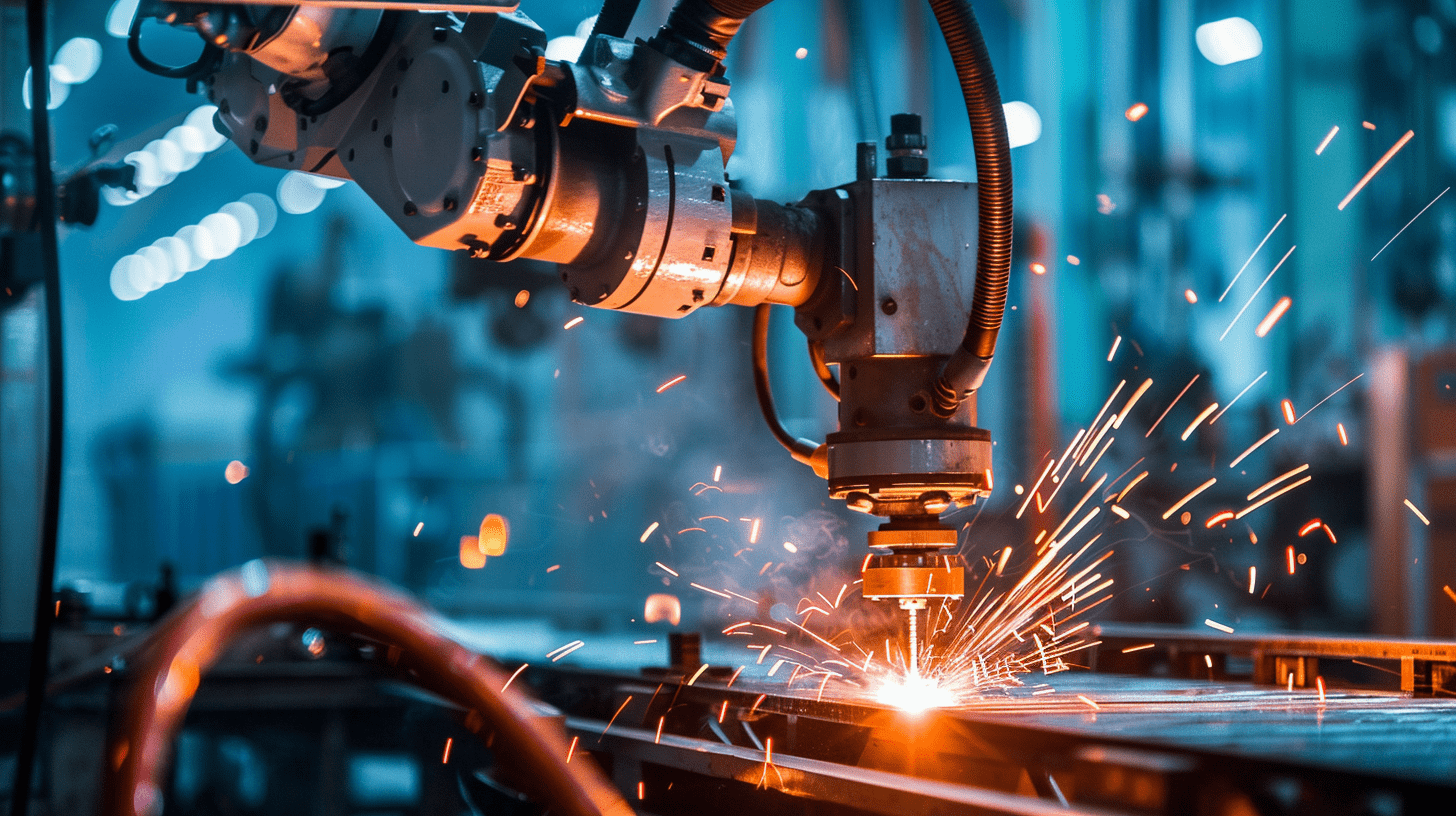

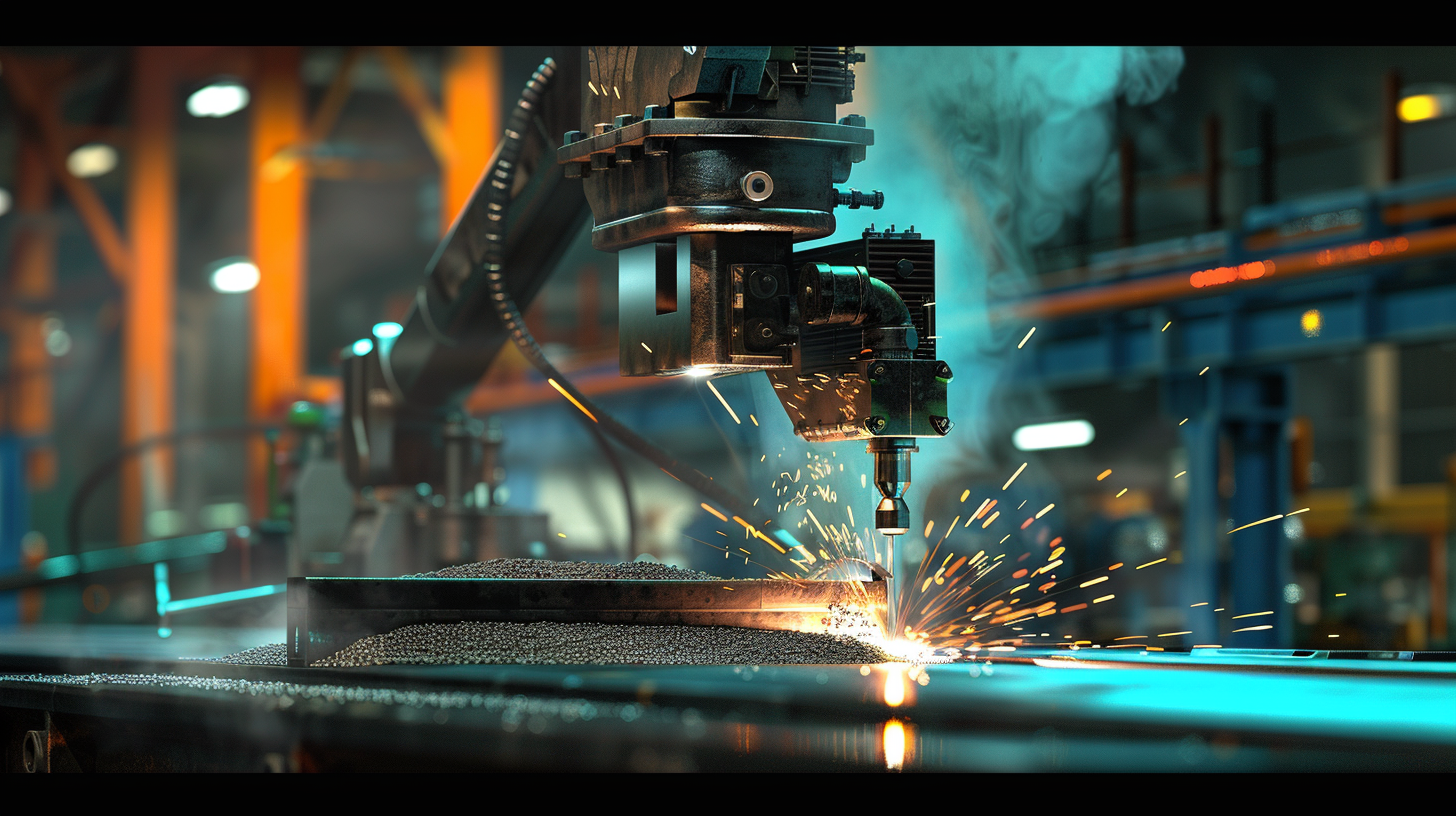

The process of joining two different metals such as stainless steel, brass, aluminium, iron, bronze etc. is called welding. A filler is used to hold those metals together during the joining process.

Types of Welding Machines

The welding process requires a huge amount of energy such as electric arc, electron beam, laser, gas flame and many more. The equipment used for the welding process are known as welders or welding machines. Some types of welding machines are as follows:

- MIG Welding Machine

- TIG Welding Machine

- CO2 Welding Machine

- MMA Welding Machine

- MAG Welder

Importance of Welding Machines

Welding is an essential process in various industrial sectors such as aerospace and construction as it offers precision and reliability. It is important to know the following advantages of welding in this fast-paced and innovative world:

- Structural Integrity: Welding may go unnoticed but it is an integral part of the manufacturing process. Welding creates strong bonds between the two metals which helps them to withstand force, tension and temperature during difficult times.

- Efficiency: In terms of economics, welding offers an incredible performance by merging different contrasting metals into a cohesive structure. Welding benefits in saving time and cost reduction as well. Though, welding looks like an expensive process in the beginning, but it is a benefit for the long term as it reduces chances of paying individual dividends.

- Melting Pots of the Industry: Welding can be termed as the melting pots of the manufacturing industry. It is a process used across various sectors where precision is a requirement. Industries such as aerospace and shipbuilding use welding to maintain the integrity of the manufacturing process.

- Advanced Innovations: There have been a lot of advancements and modifications in the welding process in recent times. Various new and innovative systems have been developed by combining welding processes with material sciences. One of the most innovative systems are cramped underground systems with nanotechnology-based designs.

- Automation in the Welding: Automation acts as an important aspect of welding while creating the welding arc. Welding can make the process easy without much need for human interactions due its properties of precision and accuracy. As this process requires minimum human interactions, it can be operated 24/7 and offer high end and desirable outputs.

Industries that Use Welding

Below stated are some of the industries that rely on welding and use different type of welding techniques:

- Aerospace: In aerospace, welding is used in making various parts of the planes such as fuselages, wings and engine. Those high-quality welds help the plane to bear difficult situations such as temperature or pressure fluctuations. TIG welding is used to make aircraft frames whereas MIG welding is used in the production of larger parts of the planes.

- Construction: Welding is used in all 3 types of construction activities which are Infrastructure, Building and Industrial. In terms of infrastructure construction, welding is used in the making of bridges, tunnels, highways and pipelines. In building construction, welding is used in the making of the steel frames for skyscrapers, commercial complexes and residential buildings. It is also used in installing metal roofing and staircases. In terms of industrial construction, welding is used in the making of power plants, factories and heavy-duty structures.

- Oil and Gas Industry: Welding is used for the construction of pipelines in oil and gas industry. It helps the pipelines to be leakage-free and make it strong for high temperatures and difficult environmental conditions. Welding types such as SMAW and FCAW are used in the construction of offshores and remote pipelines as they offer reliability at a very low cost.

- Automotive Industry: In the automotive industry, welding is mainly used in vehicle assembly and repairs. It is an essential part of manufacturing the parts of a car such as the body, chassis and exhaust systems. In vehicle assembly, TIG welding is used in applications that require precision. In terms of repairs and fabrication, welding is used in functions such as improving the chassis and repairing the broken parts of the car.

- Shipbuilding and Maritime: One of the most abundant uses of welding is in shipbuilding as it demands tough weights to repair the hulls. Stick welding machines are used in this industry as they are more versatile and can make the joints durable even in extreme windy conditions. Another benefit of using welding in ship building is corrosion control as they can save the ships from corrosive sea water by minimizing the oxidation.

- Energy and Nuclear Industry: Welding is used in the manufacturing of boilers, turbines and wind structures of power plants and renewable energy infrastructures. Even the nuclear industry requires welding for their facilities and auxiliary structures as they are corrosion resistant and offer strong bonds making it safer in harsh and hostile conditions.

- Art and Sculpture Industry: TIG welding is one of the commonly used welding machines by the artists and sculptors. This welding process allows them to create unique sculptural and metal designs with precision without degrading the quality of the material.

- Medical and Food Industry: Both medical and food industries require a clean welding for their equipment and machineries. It is important for both the industries to keep their equipment contaminant free which is easily achievable with the help of clean and smooth welding.

Take Away

This is a brief explanation about the importance of welding machines and the different sectors that use them. We hope this information will be effective for you. Please let us know through your valuable feedback and the suggestion in the drop box.