Introduction

Metal Fabrication is an essential process of the welding industry and its innovation has become a necessity in today’s fast-paced world. Modern industries demand evolved technologies with high precision, efficiency and sustainability. Thus, innovation in metal fabrication is a need to cater these demands.

Importance of Innovation in Metal Fabrication:

Below stated are some of the reasons why innovation in metal fabrication is a need in today’s welding industry:

- Evolving Industry Demands: The need for advancement in metal fabrication has grown due to recent evolution in technologies. Companies have started to produce more complex and précised components adaptable for these innovations. Innovation in metal fabrication also helps in anticipating future needs and ensuring industries’ responsiveness to changes in the market. Some of the sectors that are in forefront in terms of the need of these innovations are aerospace, automotive and renewable energy.

- Technological Integration: According to the researches, integration of technologies can be considered a heart of innovation in metal fabrication. Various software such as computer-aided design (CAD), computer-aided manufacturing (CAM) and robotics require technology that can revolutionize the design, production and assembly of metal components.

- CAD and CAM Software: These are some common software used for précised designing and planning and ensure the manufacturing of every part with exact specification. They also identify potential issues beforehand by simulating the fabrication process. The problem-solving capacity of those software leads to reduction of risks and improves the overall efficiency of manufactured parts.

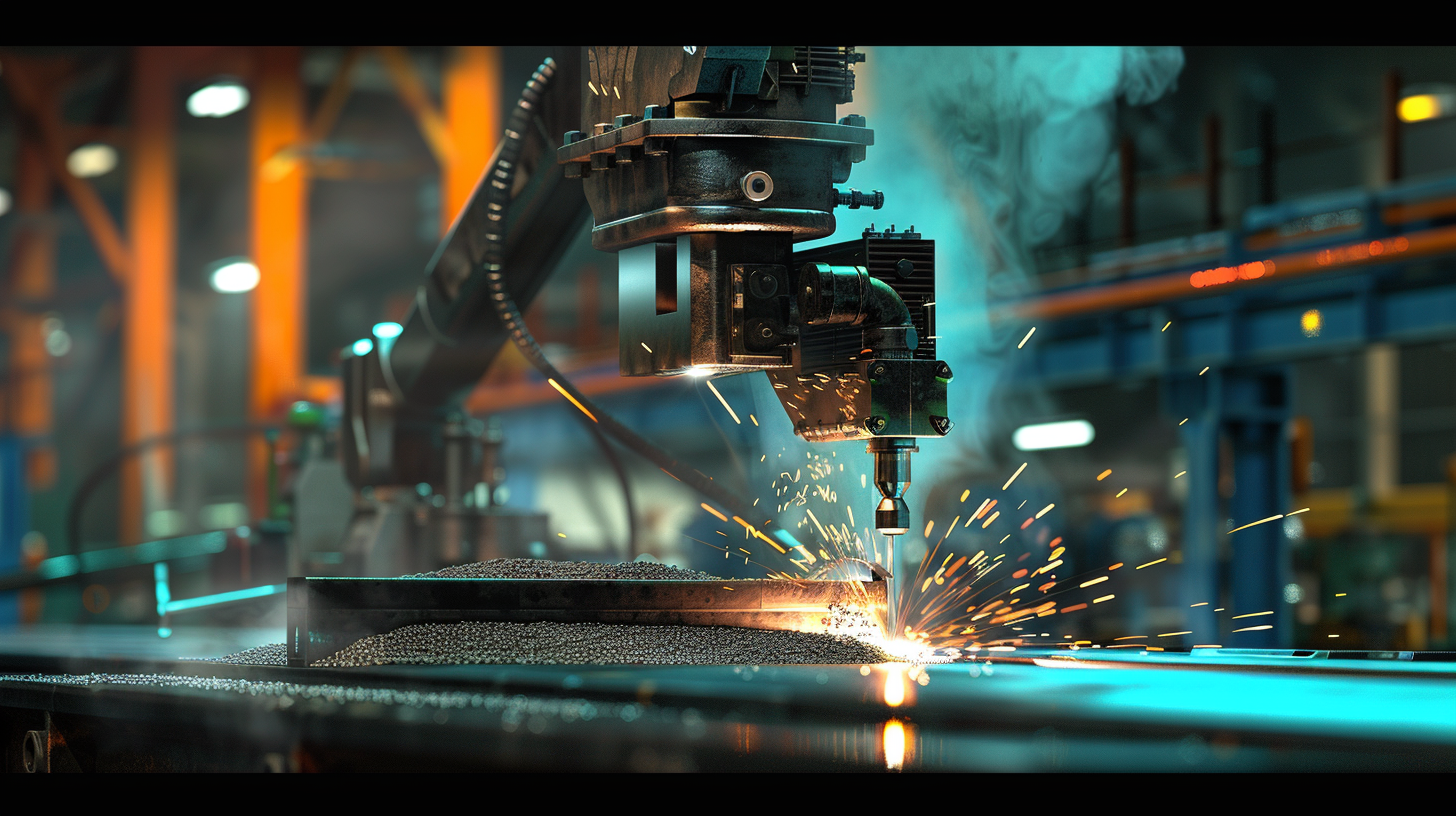

- Advanced Robotics: Robotics is a key aspect of modern metal fabrication as it offers both precision and repeatability. Robots tend to carry out processes such as welding, assembly, cutting, etc. more accurately than humans and offer products of higher quality. Apart from this, the use of robotics also improves the safety of the workplace and requires minimum human intervention.

- Sustainability and Efficiency: Apart from the technical specifications, innovation in metal fabrication also focuses on sustainability and efficiency. It focuses on minimizing environmental impact by recycling materials, and reducing energy consumption. These innovations also lead to optimization of the products and save time and cost while delivering high quality products.

- Recycling and Waste Reduction: Recycling has been adopted by a lot of modern metal fabrication shops to reuse the scrapped metal and reduce the waste. It benefits the environment and saves the cost as well. Also, various modern techniques such as laser cutting and CNC machines reduce waste, offer précised cuts and minimize errors.

- Energy Efficiency: Another benefit of innovations in metal fabrication is generation of more energy-efficient processes. The modern machinery tends to consume less energy and deliver a high performance. Also, modern welding techniques use less energy consumption than the traditional methods. Thus, the savings of this energy leads to low operational costs and less carbon generation.

- Sustainable Materials: Sustainable materials such as recycled metals and eco-friendly coatings are commonly used in today’s world. These materials tend to meet the desired quality standards while minimizing adverse impact on the environment.

Innovative Metal Fabrication Techniques

Laser Cutting and CNC machining are two innovative techniques of metal fabrication.

- Laser Cutting: Laser cutting is an essential technique in modern metal fabrication as it offers precision, speed and versatility. In this method, a focus laser beam is used to cut the materials with accuracy and produce the clear edges. Those intricate details are hard to achieve using traditional methods which makes the laser cutting process more beneficial. This process also has advanced features such as automatic focus adjustment and real-time monitoring. Those features minimize the need of manual intervention and enhance precision and efficiency. Below stated are some of the advantages of Laser Cutting:

- Precision: Laser Cutting offers tight tolerance power which helps if fitting the parts perfectly.

- Speed: Laser cutting maintains high speed which reduces production time.

- Versatility: Laser cutting can be used for a wide range of materials such as metals, plastics, etc.

- Waste Reduction: Laser cutting reduces waste which helps in saving the cost and contributing to sustainability.

- CNC Machining: CNC stands for Computer Numerical Control Machining. This method uses tools controlled by the computers to remove materials from a workpiece and offer high precision and repeatability. This method is considered ideal for producing complex parts with tight tolerance and detailed geometries. The most recent feature of CNC machining is multi-axing which is used for the creation of complex parts in a single setup. Below stated ae some of the advantages of CNC Machining:

- Consistency: Apart from precision, CNC machining offers consistency in the quality of the parts.

- Complex Geometries: This method is ideal for creating intricate shapes and complex designs which are difficult to achieve by using a manual machine.

- Efficiency: This process also reduces production cost and human intervention.

- Flexibility: These machines can be programmed for various tasks which make them efficient for both small and large productions.

How Aavishkar Group ARC Welding Solutions Drive Offers Precision

Aavishkar Group offers a wide range of welding solutions using various methods such as cutting, drilling and beveling. Some of the key suppliers of Aavishkar are Panasonic, Aotai, Koike, BDS, etc. It also focuses on delivering the best products created using modern metal fabrication.

Take Away

This is the brief explanation about the necessity of innovation in the metal fabrication industry and services Aavishkar group provides in this field. We hope this information will be effective for you. Please let us know through your valuable feedback and the suggestion in the drop box.