Introduction

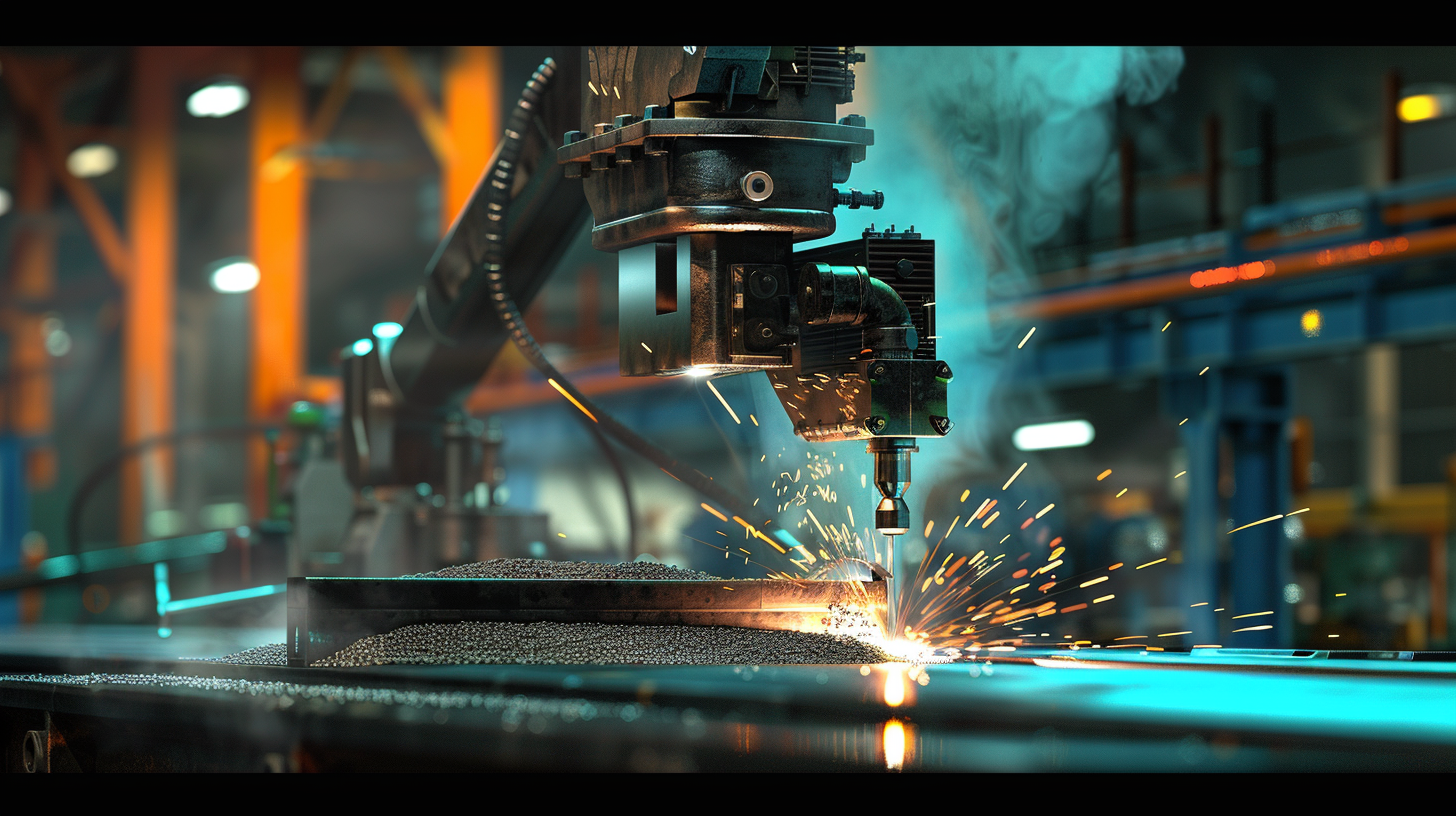

Welding Training with digital technologies is a new step towards evolution where technical discipline is taught and learned. This process includes usage of digital tools, virtual environments and interactive platforms that help in development of both practical and theoretical skills. Those developments are done through simulations, online training and media resources. This form of training does not depend on physical workshops and does not require constant presence of the instructors. It opens the doors for large-scale virtual training along with personalization, progress tracking and automated evaluation.

Welding training with digital technologies basically means accessing such an environment for learning where knowledge is given through précised simulations, controlled and practical exercises with interactive digital content. With the help of these tools, students can obtain technical competencies, correct errors and develop motor skills without being exposed to thermal and electrical risks. This training is different from traditional training as it offers remote access, instant feedback and flexibility in study schedules.

Advantages of Virtual Welding Training

Virtual welding training is an effective, safe scalable form of training in this modern era of welding. It meets the demands of both the industrial sector and ongoing learning needs of the professionals. Below stated are the advantages of virtual welding trainings:

- Flexibility and Accessibility: The biggest benefit of virtual training is that it has the ability to offer asynchronous learning which means the students get access to contents, practice modules and evaluations based on their schedules. This approach is beneficial and valuable for working technicians, university students and those individuals who need to balance trainings along with their other responsibilities. Apart from this, virtual training also removes geographic barriers by providing access from any location. After the introduction of virtual training, one won’t need to travel to a designated training center. All one requires is an internet connected device that can access the simulators, multimedia resources and evaluation resources. This benefits the people living in remote areas, regions lacking specialized infrastructures and corporate internal training programs.

- Adaptability: The digital platform-based model of welding instructions caters to the needs of a diverse audience. It can be used by both entry-level trainees and maintenance engineers who require skill updates. It also provides complexity and content depth to users. This adaptability of virtual training benefits in various sectors such as industrial, educational and institutional. In all these sectors, personalized learning makes a difference between superficial training and effective education. For example, in the industrial sector, companies tend to design training pathways aligning with their specific processes. In the educational sector, certified programs are included in technical curricula. In the government sector, standardized competencies can use those trainings to offer large-scale professional quality.

Welding Simulators as the Future of Welding Training

The technical welding training has adopted welding simulators as a new advanced technology due to increasing need of modernizing educational processes and on the growing demand of qualified welders. These simulators expand the parameter of virtual training by offering a much safer, efficient and scalable learning experience. Simulators permit the students to practice the welding techniques in a digital environment by replicating the physical, visual and auditory conditions of the real operation faithfully. Simulators also eliminate the risk of heat, gases and high-powered equipment and create an ideal space for trial and errors. The chances of physical or economic consequences reduce with the help of simulators.

Benefits of Welding Simulators

Apart from replicating the real-world environment, modern welding simulators also incorporate sensors, artificial intelligence and data analysis. Those features offer a more précised and personalized training experience to students. Below stated are some of the benefits of welding simulators:

- Pedagogical Benefits: Welding simulators have the ability to enable risk-free repetition which is their biggest advantage. In traditional settings, mistakes such as accidents, equipment damage or material waste are very common. However, simulated environments reduce chances of those mistakes and allow students to practice for nth number of time until they master the technique. Apart from this, simulators also provide immediate feedback with the help of visual reports and specific performance metrics. These reports and metrics include the data about travel speed, torch angle, and arc distance. This real-time analysis helps students to accelerate their learning processes. Another big advantage of welding simulators is the ability of real-time error connection. Welding simulators tend to identify technical deviations as they occur and offer the corrective feedback to the user. This helps the students to internalize best practices since the early stages of training. This procedure saves time and allows the instructors to focus on the strategic concepts of instructions.

- Economical and Safety Benefits: Simulators tend to reduce the material cost significantly by eliminating the constant use of electrodes, shielding gas consumables or base metals. This is a huge benefit for welding training from the point of view of operational standpoint. Simulators also reduce wear on equipment and extend their lifespan which leads to minimization of maintenance expenses. Even in terms of safety, simulators are considered ideal for beginners as the minimize the risks of burns, electric shocks and exposure to toxic fumes. Simulators tend to protect students and improve their safety in technical training. This encourages more people to pursue welding as a career.

Take Away

This is the brief explanation about welding training with different technologies, its advantages, role of welding simulators and benefits of those welding simulators. We hope this information will be effective for you. Please let us know through your valuable feedback and the suggestion in the drop box.