Home » TIG

Tungsten Inert Gas (TIG) welding, also known as Gas Tungsten Arc Welding (GTAW) is an arc welding process that produces the weld with a non-consumable tungsten electrode. TIG welding is suitable for all types of carbon steels, low-alloy steels, alloyed stainless, nickel alloys, aluminium and its alloys, copper and its alloys, titanium, magnesium, and other nonferrous alloys. The use of an infusible electrode makes TIG welding particularly suited for metals only a few millimetres thick. TIG welding is also widely applied in mechanized systems either autogenously or with filler wire. However, several ‘off-the-shelf’ systems are available for orbital welding of pipes, used in the manufacture of chemical plants or boilers.

The systems require no manipulative skill, but the operator must be well trained.

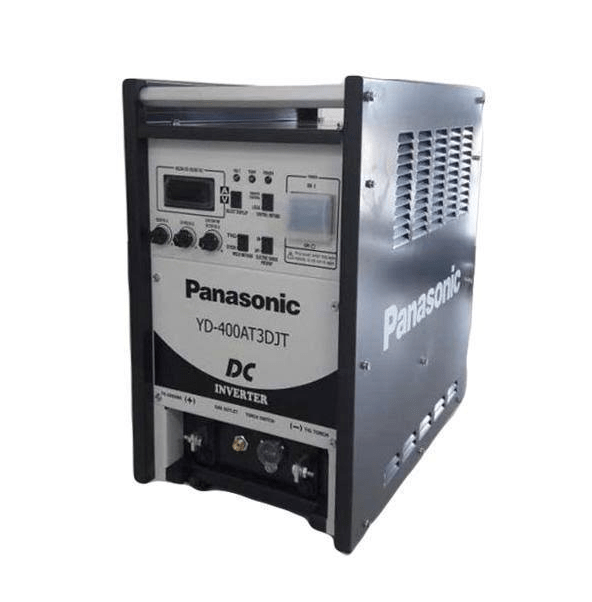

We are the authorized dealers for West India Distributor for TIG welding machines of Panasonic and Aotai. Kindly browse through the catalogue of the listed products and submit a request for the proposal of your desired equipment. Our team will surely get back to you with the same.

TIG welding (also known as Gas Tungsten Arc Welding, GTAW) uses a non-consumable tungsten electrode and an inert shielding gas (typically argon) to create a weld arc, and optionally a filler wire is added.

It is suitable for many materials — carbon steels, low-alloy steels, stainless steels, nickel alloys, aluminium and its alloys, copper and its alloys, titanium, magnesium and other non-ferrous metals.

Because of its precision and clean welds, it is used when weld quality, aesthetics or thin sheets are important.

When selecting a TIG welding machine, key factors include:

Material type you plan to weld (for example: steel vs aluminium) — aluminium usually needs AC output, steel may use DC.

Material thickness — thicker plates may require higher current/amperage, higher duty cycle.

Power supply / phase — single-phase vs three-phase, voltage availability.

Features such as AC/DC switching, pulse welding modes, high frequency start, duty cycle ratings.

Budget & usage intensity — for industrial, heavy-duty use vs occasional workshop use.

Thus, match your machine’s specs to your metal type + thickness + operational environment + budget.

Advantages of TIG welding:

Very high quality, clean welds with minimal spatter and slag.

Capable of welding a wide variety of metals (including non-ferrous) and thin sheets.

Good for precision work, the weld appearance matters, or materials are difficult to weld.

Limitations of TIG welding:

More demanding skill-wise: requires steady hand, operator experience.

Lower deposition rate (slower) compared to processes like MIG.

Typically higher cost per weld foot and more setup/cleaning required.

So TIG is ideal for quality over speed, but if you need high throughput for thick plates and less fine finish, other methods may be more efficient.

You can weld many materials with a TIG machine: stainless steel, mild steel, aluminium, copper alloys, titanium, magnesium and other non-ferrous materials.

Settings considerations:

For steel & stainless: DC output is common; for aluminium & magnesium: AC output is generally required (to deal with oxide layer) and often with special tungsten electrodes.

Shielding gas: typically pure argon; sometimes argon-helium mixes or other blends depending on material.

Electrode type: selecting the right tungsten composition (e.g., ceriated, lanthanated) and correct size for current.

Cleanliness: surface must be clean of oxide/contamination for best results.

Thus, when buying or operating a TIG machine, ensure the machine supports the right current type (AC/DC) and you have the right accessories for your target material.

Given the precision nature of TIG welding machines, after-sales support matters. The page of Aavishkar Group notes they are authorized dealers / distributors for major brands (e.g., Panasonic & Aotai) in West India.

Key things to check:

Availability of spare parts (torch consumables, tungsten electrodes, regulators, etc).

Service support / warranty from the supplier/distributor.

Technical training or operator consultancy, since TIG welding requires deeper skill.

Documentation, catalogues, user manuals, and ease of obtaining consumables (shielding gas, wires) locally.

Ensure the machine has local voltage compatibility, and support for installation/commissioning.

Ensuring these support aspects will protect your investment in the long run — especially when operating industrial-grade TIG equipment.