Introduction

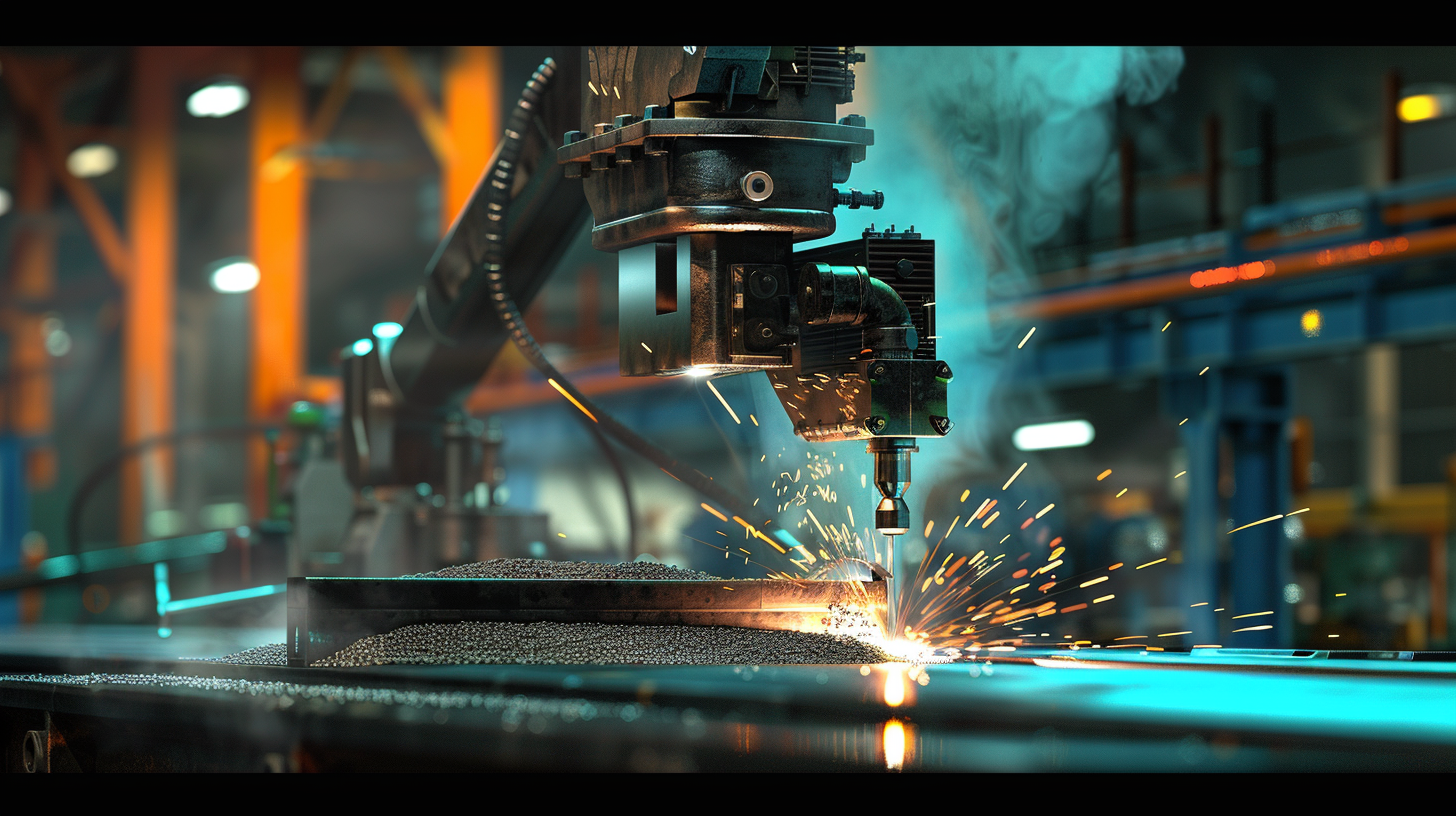

It is important to choose the correct welding consumable to ensure various factors such as durability, efficiency, and lifespan of the industrial equipment and their components. The incorrect choice of welding consumables can result in premature failures, increase in downtime and costly repairs. Thus, the professionals choose the correct welding consumables based on various factors.

Types of Welding Consumables

There are 3 most common types of welding consumables. These are filler metals, electrodes and fluxes. Filler metals are used to join two pieces together during the welding process. Electrodes are used to strike an arc while welding with electric current and fluxes are used as a barrier to keep moisture and air away from the weld. It also helps in removing impurities from the joint area.

Factors to be Considered While Choosing the Welding Consumables

Below stated are some of the key factors that a welder or maintenance professional considers while choosing the welding consumables:

- Identification and Understanding of the Problem: Every industrial equipment is subject to different kinds of wear. Identification of primary wear mechanisms helps in certifying the selection of right consumable. Some of the types wears can be:

- Abrasion: This can be found in mining, quarries, cement productions while sliding of hard particles or rubbing against the surfaces. The best consumable for this wear can be highly alloyed steels with tungsten contents.

- Impact: This can be found during mining, recycling and in railways due to large chips and scratches. The best consumable for this wear can be hardening manganese steels or highly alloyed steels.

- Metal-Metal: This wear is found in steel manufacturing and forging during a relative moment between two metallic parts. Best consumable for this wear can be tool steel or stainless steel.

- Corrosion: This happens in sectors such as naval, petrochemical, pulp and papers due to the chemical reactions and leads to deterioration of the materials. The best consumables for corrosion can be austenitic stainless steel or nickel-based alloys.

- Temperature: This happens in sectors such as power generation, forging, steel manufacturing, etc. where high temperatures tend to affect the properties of the materials. The best consumable for this wear can be stainless steels, or nickel and cobalt based alloys.

- Matching the Consumables with Welding Processes: The welding consumables are not compatible with every welding process. Thus, these consumables should be chosen in order to align them with the welding process. For example, the FCAW welding process is compatible with cored wires whereas the GMAW process is compatible with solid and metal-cored wires. Similarly, GTAW is compatible with rods and filler wires, SMAW aligns with covered electrodes and SAW aligns with wire and flux.

- Compatibility of the Base Material: It is important to determine the composition and properties of base metals while choosing the consumables. Some of these considerations are:

- Steel: This can be matched to high-carbon steel with low, medium and high grades.

- Stainless Steel: This can be used against corrosion.

- Cast Iron: It can be used as a special electrode to prevent cracking.

- Dissimilar Metal: These metals such as nickel alloys are used to ensure compatibility.

- Consideration of Environmental Factors: Environmental factors play an important role in the selection of consumables. For example, high temperatures in power or cement industries use heat resistant alloys, corrosive environments in petrochemicals or marines use consumables with anti-corrosive properties and outdoor welding in construction and railways use open arc consumables.

- Performance vs Cost: Welding consumables are available in a wide range of prices. However, cheaper consumables may cause the need for higher long-term costs as they lead to increased wear and frequent repairs. Some of factor that should be considered while keeping performance and cost in mind are:

- High-hardness wear-resistant wires may require higher upfront cost but it extends the service life as well.

- Low-cost general-purpose electrodes can be used for basic repairs but should be used in heavy wear environments.

- Specialty alloys are more expensive but are essential for extreme applications.

Common Mistakes and Ways to Avoid Them

Some of the common mistake while choosing welding consumables are as follows along with the ways to avoid them:

- Choosing Consumable Based on the Price Alone: The consumable must be chosen by keeping various factors in mind and not only the price. If they are chosen solely on the basis of price, it may lead to frequent re-welding and increase the cost of investment in welding consumables.

- Ignoring Base Material Properties: It is important to consider the properties of the base metal while choosing the welding consumables. If this factor is not considered, it mismatches the consumables and can lead to poor fusion or cracking.

- Skipping Pre-Welding Testing: It is advisable and beneficial to carry out the pre-welding tests as those small-scale trials can help in choosing the correct welding consumable.

- Neglecting Welding Parameters: Welding parameters should be considered while choosing as defects such as incorrect voltage, travel speed or shielding gas can affect the weld’s quality.

Testing of the Consumables

The consumables should be tested through real-world testing to ensure the desired performance. Conducting those trials helps one to confirm its capability with the properties of the base material, evaluate its wear resistance capacity under difficult situations and optimize welding parameters before large-scale implementations.

Take Away

This is the brief explanation about the importance of choosing the welding consumables, factors to be considered while choosing them and advantages of testing their ability beforehand. We hope this information will be effective for you. Please let us know through your valuable feedback and the suggestion in the drop box.