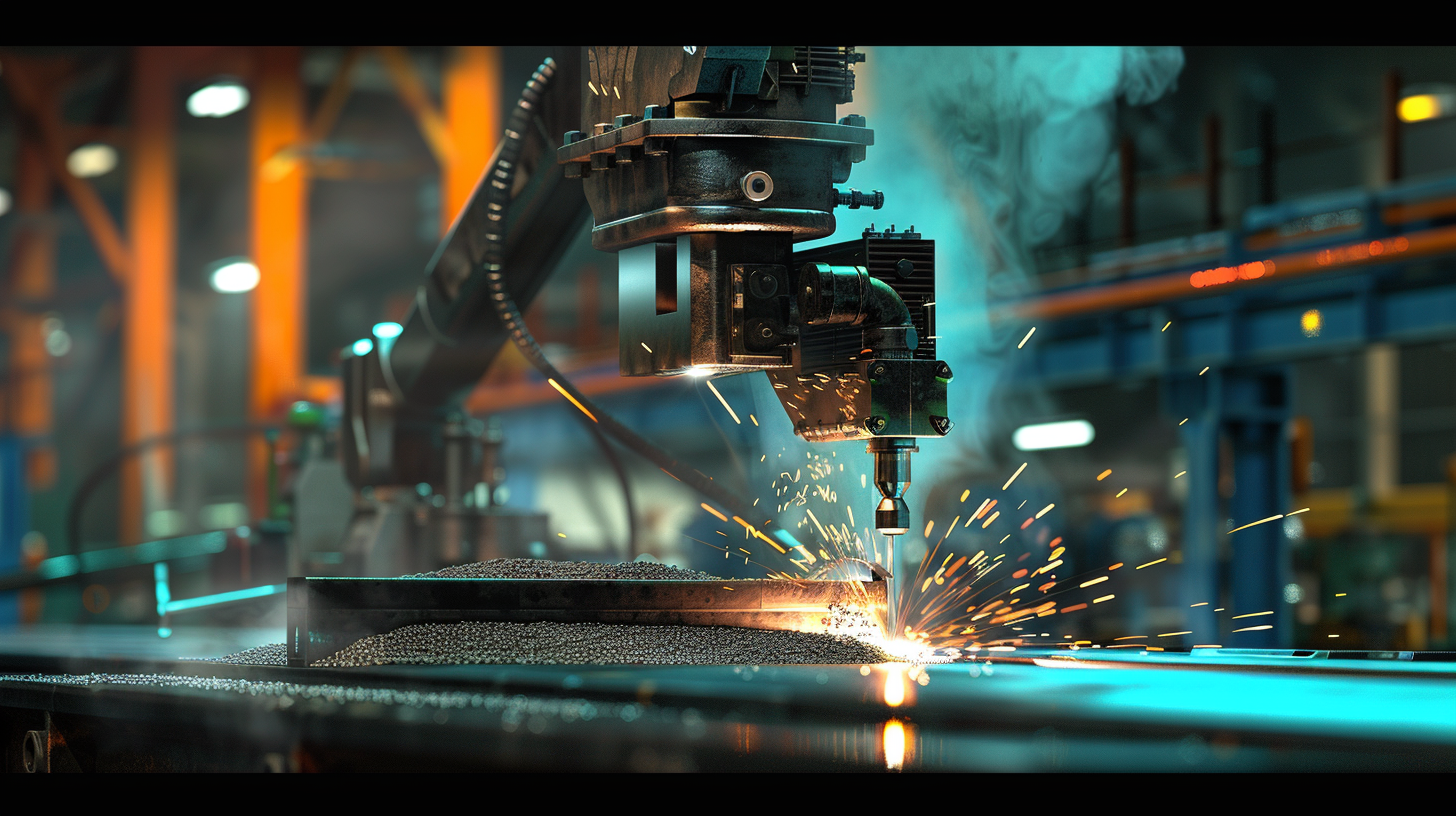

Introduction: – Pipe Welding

Pipe welding is a type of welding process used to weld long sections of pipes. In this process, two or more pipes are combined through the action of heat and pressure to create a powerful and leak-proof joint between the pipes. The contrast between a regular welding and a pipe welding is that pipe welding includes curved surfaces and requires précised techniques to allow pipes to sustain high pressure in a durable and safer way. The joints created through pipe welding technique cannot be broken easily and tend to resist high temperatures, high pressures and corrosive materials as well. Pipe welding is considered one of the vital techniques as it deals with oils and gases, chemical processes, construction and plumbing. In all these sectors, pipe welding is highly demanded to transport oils and gases through these pipelines.

Advantages of Pipe Welding

Below stated are the advantages of pipe welding in sectors like construction and maintenance:

- Strength and Durability: The pipes welding through this process are seamless in joining. They are super strong in terms of handling pressures and extreme temperatures even in harsh conditions. Thus, pipe welding is considered ideal in crucial industries such as transportation of oil, gases and chemicals.

- Leak-Proof Connections: Pipe welding joints pipes permanently unlike mechanical joints that use thread or seals. The strong bonds of pipe welding allow the system to be leak-proof and minimize the chances of spills and other safety concerns.

- Cost-Effective for Bigger Projects: Pipe welding does not require extra parts such as flanges and couplings which reduces the cost of the operation. This makes it more ideal for large projects like pipelines and also saves the labor costs.

- Versatility in Applications: Pipe welding is used in various industries from construction, manufacturing, energy and utilities. It is adaptable to various sizes, materials and positions making it ideal for a wide range of projects.

- Custom Designs: Pipe welding allows customization since the process of putting pipes together in peculiar layouts. It can also adjust the pipes according to necessary configurations according to the project making it a customized process.

- Long-Term Reliability: As the joints created by pipe welding are stronger and more durable in comparison to mechanical joints, it reduces the maintenance and replacement needs. The efficiency of pipes increases the overall performance of the operations and also saves costs.

Introduction- Pipeline Welding

Pipeline welding is also known as girth welding. It is a fabrication process that connects the pipes and forms a network. This type of welding requires a combination of skill and knowledge. The welders must be able to weld a wide range of positions and situations even in remote locations and harsh weather conditions.

Challenges and Rewards of Pipeline Welding

The pipeline welding process is both challenging and rewarding. The biggest challenge of this process is mastering different welding positions and adapting the constant change in the diameters of the pipes. Welders often have to work in physically demanding environments and face extreme weather conditions. However, this process also offers certain rewards such as job security, competitive salary and opportunity of growth in career. It also opens an opportunity to freelance or start a business.

Positions of Pipe and Pipeline Welding

Below stated are the 6 positions used in both pipe and pipeline welding:

- 1G Position (Rotated Flat): This is the easiest position in which the pipe is horizontal and is rotated during the welding process.

- 2G Position: In this position, the pipe is fixed vertically and the welders have to work on the sides of the pipes.

- 3G Position: In this position, the pipe is fixed vertically and the welders have to work on the top and bottom of the joint.

- 4G Position: In this, the pipe is fixed overhead making it a difficult process. The welders have to work on the bottom of the pipes in this position.

- 5G Position: In this step, the position of the pipe is horizontal, fixed and un-rotated and the welders are expected to work around the pipes.

- 6G Position (Inclined Fixed Position): This is the most challenging position as the pipe is set on 45 degrees and fixed at one place. The welders are expected to work on all the sides of the pipes.

Difference Between Pipe Welding and Pipeline Welding

Below stated are some of the key differences between pipe welding and pipeline welding:

- Application and Scope: Pipe welding is usually more suitable for small-scale systems such as plumbing, HVAC operations, etc. whereas pipeline welding is considered ideal for large-scale projects including oil, gas and water pipelines.

- Environment: Pipe welding is mostly done under a controlled environment like workshops or on-site construction areas whereas pipeline welding is an outdoor job in which welders have to work under harsh conditions such as temperature, wind, etc.

- Materials and Pipe Sizes: In pipe welding, various pipe sizes can be used and welded with different materials such as steel, copper and alloys. On the other hand, pipeline welding is made from pipes with big diameters and includes only steel pipes to store the liquids and gases.

- Techniques and Positions: Various types of techniques and positions are used in pipe welding depending upon the application whereas in pipeline welding, SAW and SMAW technique in 5G and 6G position is considered more suitable.

- Objective: The good and strong quality joints of pipe welding offer functionality and reduce safety issues whereas the pipeline welding is known for offering integrated and leak-tight performances making the transport of materials safe.

Take Away

This is the brief explanation about pipe welding, pipeline welding and the difference between these two techniques. We hope this information will be effective for you. Please let us know through your valuable feedback and the suggestion in the drop box.