Introduction

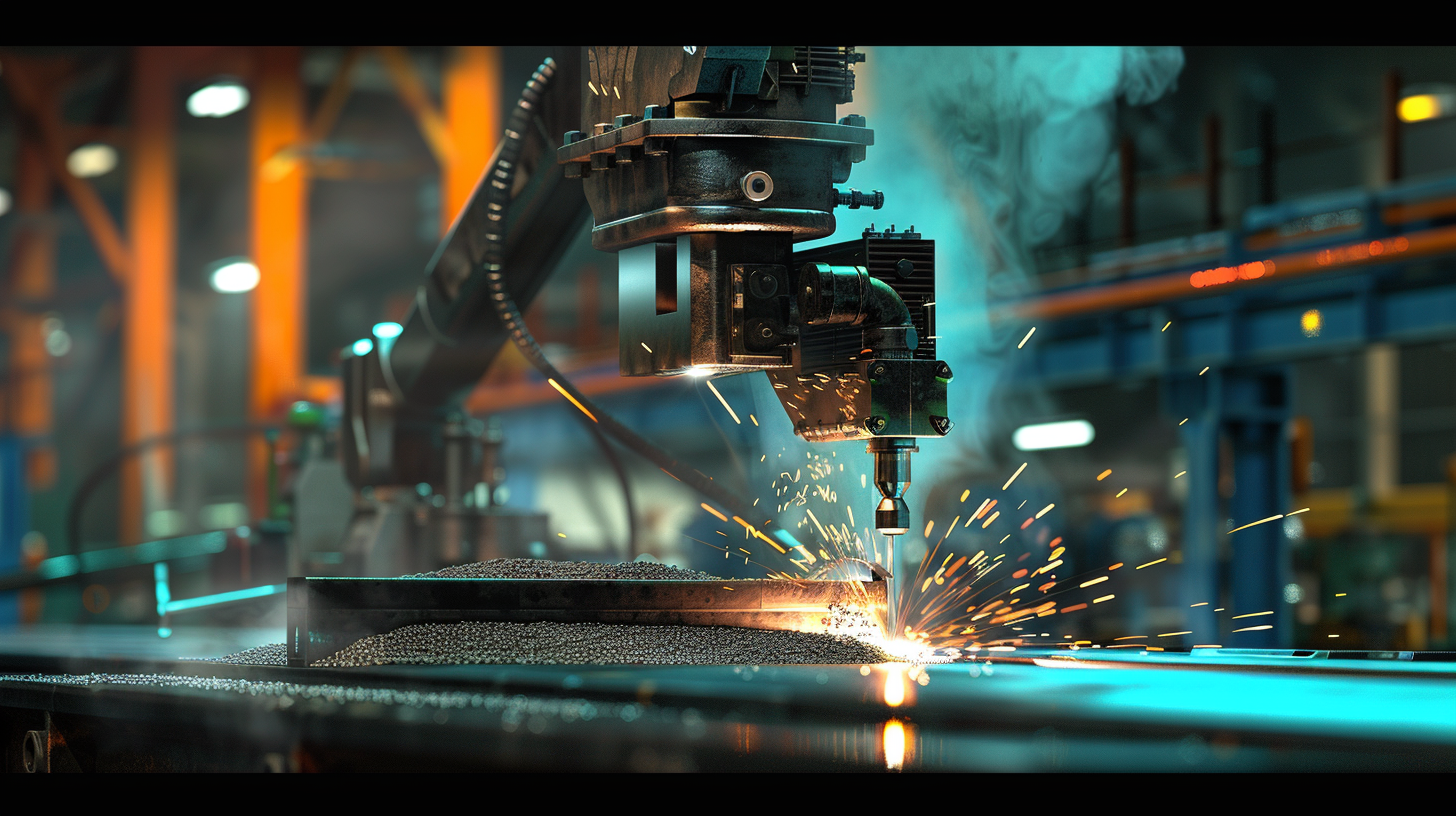

The acronym of Submerged Arc Welding is SAW. It is a long-established and automated type of welding in which an AC arc is between the heavy gauge workpiece and the continuously fed electrode. This arc is shielded by a granular flux material of different varieties, deposited directly. This stream of flux is fed to the weld zone to provide exclusion of atmospheric contamination and a reducing environment. This flux also contains cosmic arc energy in the melt pool and improves the quality and application of the energy. This flux is non-adhesive and gravity-fed in nature allows the flux material to weld upwards and close to horizontal making SAW a practical process.

The submerged Welding process is mostly used for welding thick portions of the steel in various sectors such as shipbuilding, structural steel fabrication, vessel manufacturing, pipeline construction, etc. It consists of properties such as deep penetration capabilities, excellent weld quality and simple automation.

Primary Purpose and Importance of SAW

The main purpose of SAW is to weld the larger parts of the steel quickly and in a repeatable manner. This welding is more suitable for welding large structural parts, heavy-gauge plates and components requiring heavy penetration.

This welding process is one of the integral parts of the manufacturing process in various industries. SAW is known for facilitating high throughputs and allowing rapid processing of the welding. The deep penetration ability of SAW makes it extremely important while welding the thick plates and components. It produces high-quality welds with exceptional mechanical properties.

How Does Submerged Arc Welding Work

The process of SAW involves a formation of a steady and extremely high-power arc between a continuously fed electrode and the workpieces. This arc is used to melt the edges of the workpieces and the filler rod and merge them into one single and consistent melt pool. The flux cover of this welding also prevents oxidation and weld-degrading inclusions that are applied prior to the arc.

Process of Submerged Arc Welding

Submerged Arc Welding (SAW) is an extremely repeatable process. The materials and parameters of this process are useful in various applications. Thus, below stated is the process of submerged arc welding:

- Preparation of the Workpiece: The first step is to prepare the workpieces by cleaning and positioning them correctly for the welding.

- Preparation of Tubular Electrode: The next step is to prepare the tubular electrode. A tubular electrode is a material that is used to improve the melting characteristics of the arc and behave as a high-power while being applied. This electrode must be compatible with the base metals of the application.

- Striking the Arc: The 3rd step is to strike an arc between the electrode and the workpiece. This leads to a high and intense heating which melts the electrode and surrounds the material into a melt pool. The flux which covers the arc tends to melt and form a protective slag layer over the weld pool and shield it from the oxygen.

- Filling the Gap: A molten is formed after the heat of the arc melts which merges the parts and electrode materials. During this time, the electrode wire is continuously fed into the weld zone which adds the filler metal to the pool. Also, the parts or welding heads are also moved in the direction of the weld to extend the melt pool. The edge of this metal pool helps in cooling and create a strong bond between the base metals. Thus, the gaps between the workpieces and filler material are filled through the merging of the edges.

- Completing the joint: The last step is to join and overlay the slag layer formed by the flux after the welding is completed, flux is cooled down and solidified. The slag should be chipped off or be removed using an abrasion. After this step the weld can undergo additional processes such as grinding, cleaning and inspection.

Equipment Used in Submerged Arc Welding

Below stated are some of the key equipment used in the SAW process:

- Constant Current/Constant Voltage Power Module: This part is used to condition electrical energy and maintain the welding arc and can be constructed from a transformer-rectifier or an inverter as well.

- Welding Head: Welding head is also known as boom. It is used to retain and orientate the welding torch. It can be both stationary or movable. This boom either moves along the weld or can part the traverse under the boom to perform the weld.

- Electrode Wire: Electrode wire is a wire which is continuously fed to the welding joint. The feed rate, preset and dynamics of this wire is controlled by the operator.

- Welding Torch (Head): Welding torch is the delivery mechanism of the electrode wire.

- Flux Hopper/Delivery System: Flux Hopper is used to supply a flow of flux granules over the arc and the weld pool.

- Flux Recovery System: This part is used to collect and recycle the unused and over-applied flux. This part helps in controlling costs as flux is considered as a consumable value.

- Cooling Apparatus: This part is used to improve the longevity of the welding equipment.

- CNC Control Panel: This part is used to adjust and regulate the various parameters of the welding process.

Take Away

This is the brief explanation about Submerged Arc Welding, its purpose, importance working process and equipment used in it. We hope this information will be effective for you. Please let us know through your valuable feedback and the suggestion in the drop box.