Introduction

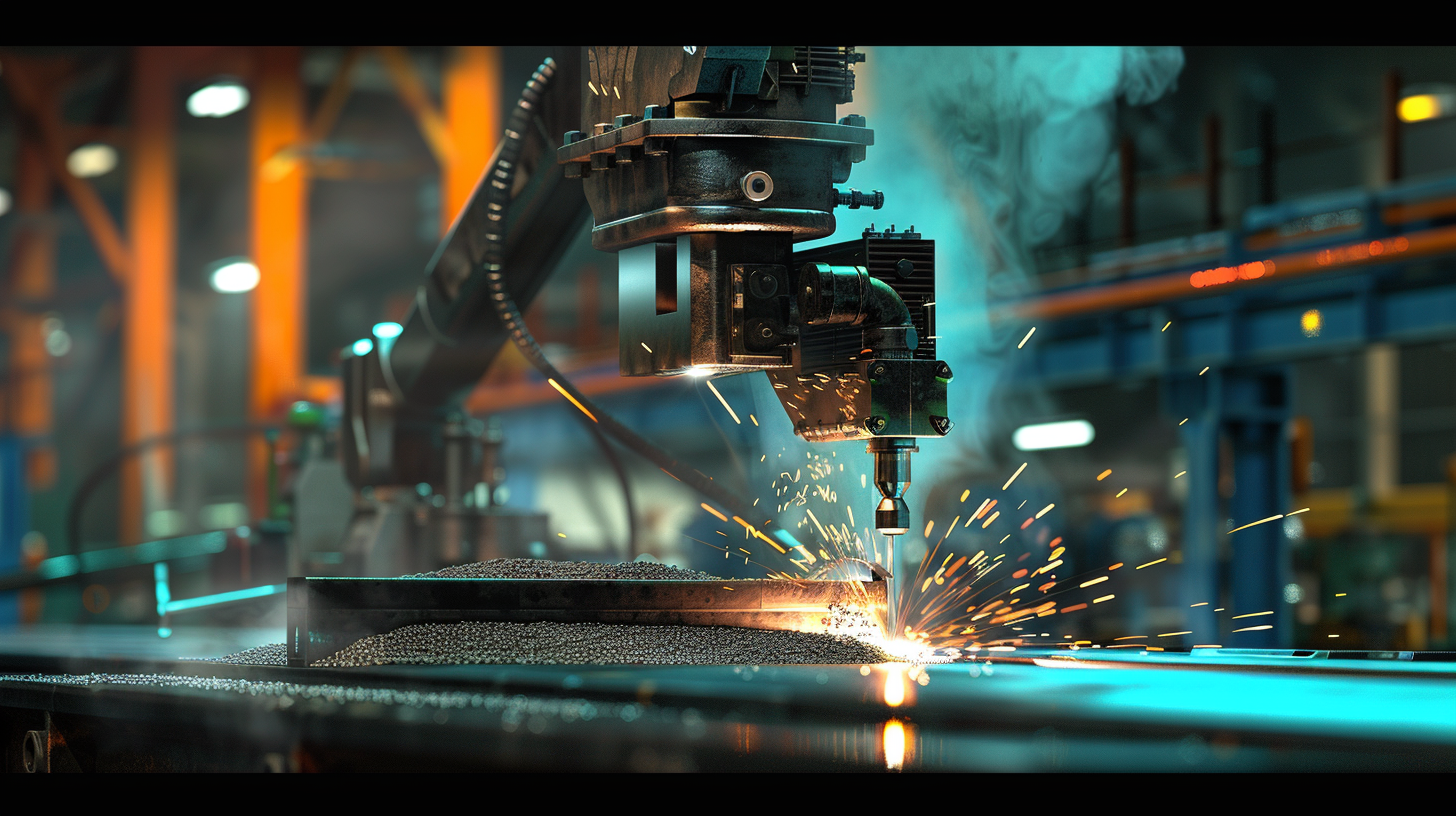

Arc welding is a method used to melt two metals together. In this process, intense heat is generated which melts two metals together and transforms them into one material. Arc welding can also be called metal fusion and is one of the reasons behind strong welded structures.

Working of Arc Welding

Two types of metals are used in the arc welding process. These types are base metals and electrodes. Electricity is used to create a circuit between these two types of metals and then attached to the welding gun. A weld of molten pool is created by removing the electrode from the base metal and generating an extremely hot arc of electricity. This hot arc can be up to 11,000 Fahrenheit. However, the weld can be affected by contaminants and gases present in the air. Thus, a wielding shield made up of inert gases is used to protect this weld during the ongoing process. This inert gas can be supplied to weld in two ways which are externally through the welding machine or through an electrode or flux coating. The way of inserting gas depends on the type of arc welding process used.

Types of Arc Welding Processes

There are 5 key types of arc welding process which are stated below:

- MIG Welding: It is a highly versatile process and can be used of different metals with various thicknesses.

- TIG Welding: It is a slow process used for welding the round things. It is difficult to learn and requires a pointed electrode for accuracy.

- Stick Welding: Stick welding uses a fixed length electrode and is used on dirty or rusty surfaces. It is also a difficult process.

- Flux Cored Arc Welding: It is a highly productive type welding used for dirty base metals. It is easy to transport and requires minimal cleanup.

- Plasma Arc Welding: It is a precise and accurate type of welding mostly used on very thin or thick base metals. It uses non-consumable pointed tungsten electrodes for its accuracy.

MIG Welding

MIG Welding is the most common and easiest type of welding. The full form of MIG is metal inert gas and is also known as GMAW which stands for Gas Metal Arc Welding. It is a semi-automatic process and is mostly used for indoor applications. It requires shelter from the wind. MIG welding gun uses a solid wire electrode that melts the two metals by generating the electricity arc. An electric current is given to the electrode which also acts as a filler and helps in the improvement of weld. The electrode holds control over the arc and generates heat that can melt filler and the base material. This process also requires shielding gas via the welding machine which guards the process from wind. MIG welding can be applied on various metals of different thickness such as aluminium, steel, nickel and some of the alloys too. This process is often used in automotive repairs, steelwork and in the manufacturing of furniture, computer parts and agricultural machines.

TIG Welding

TIG welding is also known as GTAW which stands for Tungsten Gas Arc Welding. Non-consumable tungsten electrodes are used in this process which allows precision and produces high quality welds. This is a very difficult process to learn. Apart from the electrode, it also uses a connector and a shielding gas. When the electrode is removed after being applied to the base metal, it creates a small and intense arc. This arc helps in maintaining the high quality and precision in welding. This is one of the rare processes that do not require filler metal which makes it clean and does not need regular clean up. TIG welding should be performed indoors. Thus, this process is mostly on thin metals or in metal sculptures.

Stick Welding

Stick welding is also known as SMAW which stands for Shield Metal Arc Welding. This process can be carried out both indoor and outdoor and can be applied on common metals or alloys such as steel and aluminium. As it can also be applied on dirty and rusted surfaces, it is a highly used process in repair and maintenance industries. It is difficult to learn as it requires a skill to strike a perfect arc. In this process, a fixed length stick is used coated with powdered metals. This flux forms a shielding gas when the heat is generated. At the same time, a filler material is produced through a melting electrode which creates the weld with the base metal. This process requires a lot of cleaning up as it produces a huge amount of spatter. Stick welding process is easy to transport and is used in difficult situations such as winds and rain.

Flux Cored Arc Welding

The short form of Flux Cored Arc Welding is (FCAW). This is a combination of MIG welding and stick welding as its electrode has a flux core coated with different powdered metals. The arc is formed when the electricity is passed into the base metal through electrodes. As the arc gets heated, the flux creates a gas shield around electrodes, filler metal and base metals. This process is carried out through a special technique called drag techniques where the weld gun is pulled away from the completed weld. FCAW is commonly used in heavy-duty and manufacturing industries.

Plasma Arc Welding

Plasma Arc Welding, also known as PAW is quite similar to the TIG process as it also consists of a pointed tungsten electrode. However, the difference in both the processes is that this electrode is positioned inside the torch in plasma arc welding. It keeps the plasma away from the gas shield and helps in developing the arc and weld. Plasma arc welding is highly productive as it uses non consumable tungsten electrodes which benefits in increasing precision. This process is mostly used in the electronics, aerospace, marine and healthcare industries.

Take Away

This is the brief explanation about 5 key types of welding processes and their prominent uses in different industries. We hope this information will be effective for you. Please let us know through your valuable feedback and the suggestion in the drop box.