Introduction

The motto “time is money” is very well applicable in the Welding and Fabrication industry. The achievement of the trifecta of the services: speed, quality, and affordability decides your shop’s accomplishments. These services can be completed with ease with the use of a modular fixture system. This system can enhance and influence your capacity to smoothly accommodate a variety of jobs. This article focuses on the definition, uses, and benefits of using the welding table with modular fixtures.

What is Welding Table and what does it consist of?

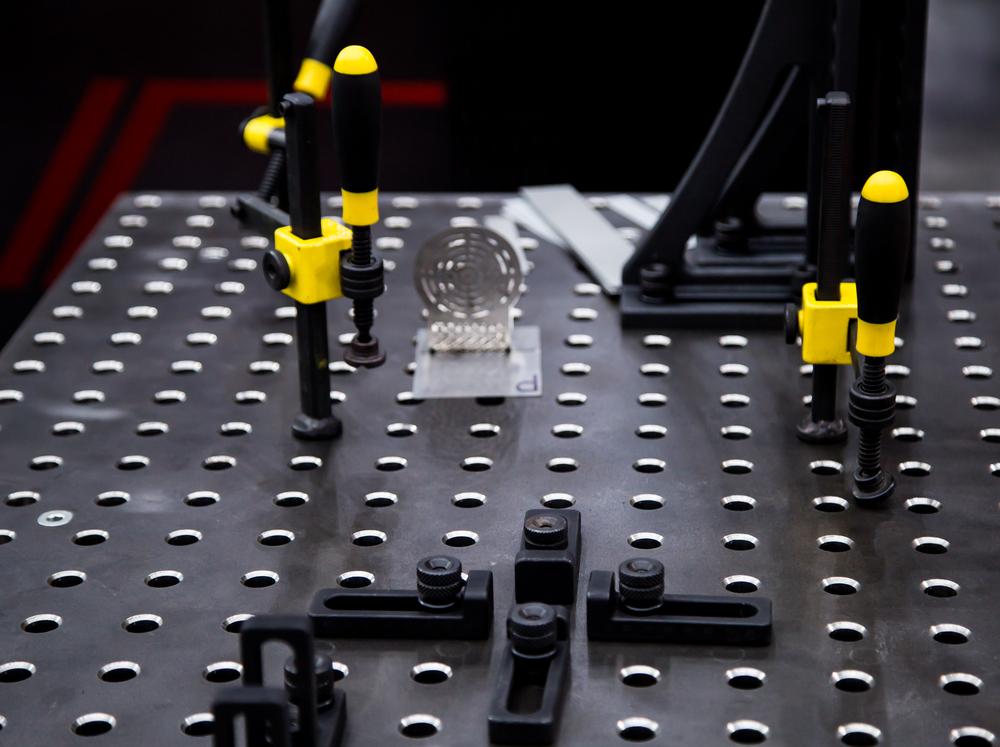

In any welder’s workspace Welding table is one of the core requirements. According to the rule, a welding table is made from steel and is basically a platform (waist-levelled) that attends as a workbench for a welder. The primary dimensions of a welding table can be from 20” x 40” to 6.5” x 13”. Its biggest advantage is that it prevents electric shocks and fire hazards.

A modular fixture system includes – a ground and a welding table that should be flat and must contain precise machine holes at any and every point on the tabletop for the setup of clamps and components. To help the welder in sitting or adjusting to a fitting position in ongoing job work, most tables have adjustable legs. Its most important property is its adaptability and to be able to repeatedly create high-volume job work.

In what ways can we use Welding Table?

First and the foremost use for a welding table are to provide a sturdy welding surface to work. Apart from that it also helps in Measuring, squaring corners, mounting, gauging, bending brakes and jigs, mounting, and electrical grounding.

What are the benefits of using a Welding Table with modular fixtures?

For precise welding, a modular welding system takes the performance productivity and expertise to another level. This includes adjustable surfaces and legs, and a widespread collection of fixturing tools such as different sizes of clamps, angles, bolts, and more. To add value to your business this system has to be calculated based on its strength, cost-effectiveness, accuracy, comfort and safety, and adaptability. The following are the key benefits:

- Cost Effective

To utilize the full capability of your team and to make the ongoing welding workshop efficient all businesses should invest in a good quality modular welding table. The job work is done much more accurately and systematically and set-ups are finished faster. And as a chain reaction, the quicker you complete your projects, the easier it becomes to take up new welding projects. As a result, not only your production increase, but you will be able to achieve returns quicker on your investment too.

- Provides adaptability and versatility

Every industry and business has different requirements and modular welding tables have a large variety of sizes to cater to those needs. Providing adaptability also means that you have one quick fix for all your job work. To make certain that your table setup fits the job you are fulfilling; they can be effortlessly extended and connected as they are modular. You also have a choice to decide on your footing depending upon the welding work. At one touch of a button, a modular welding system can change the static legs of the table to mobile legs with lockable castors or if there is continually shifting in the height; adjustments can be done on scissor lift bases too. Additionally, a wide variety of accessories is also available to fix unusual or intricate shapes easily on the table or clamp components onto various precise angles and measures.

- Enhancing the safety of a workplace

During a welding job, certain issues like – holding an awkward body position for a long time, and tolerating heavy lifting can cause fatigue, exhaustion, and even injury. But modular welding tables can be adjusted to fit various heights making the welding work user-friendly and removing any unrequired strain on their body. This reduces the downtime on projects all the while protecting their health.

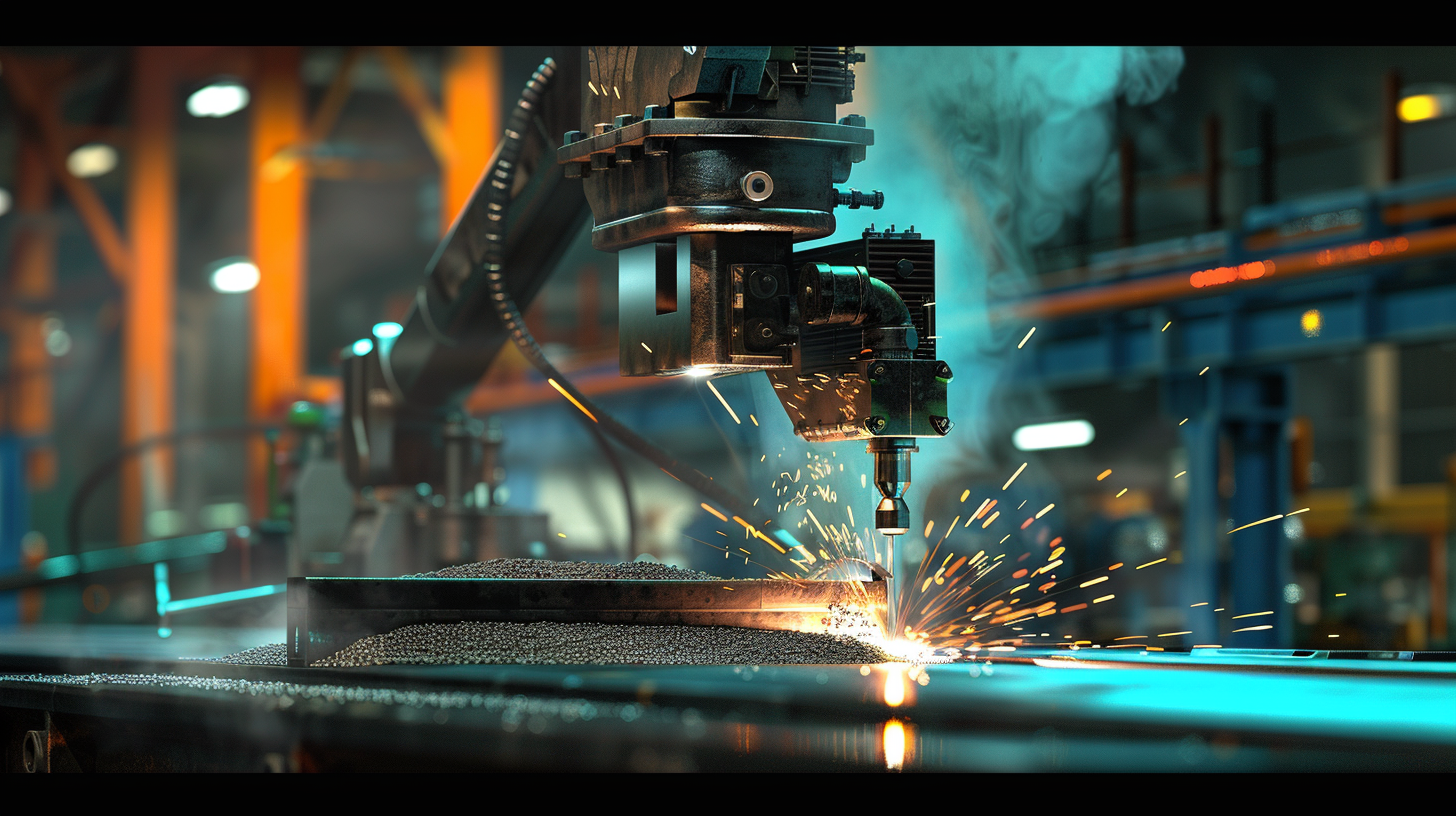

- It is a strong Workbench

The tools used by welders have excessively high temperatures, so there are sparks, smelted metal, and even hazardous debris sometimes. But modular welding tables do provide the highest safety, strength, and stability and can take a beating. They are made from carbon steel (with heat resistant surface) and won’t misshape or distort during the job. They are designed to provide maximum safety to the welders; they can handle any kind of welding work no matter how tough the job is. They are highly reliable, steady, and powerful.

- Superior accuracy

The level of accuracy provided by modular welding tables is very high and irreplaceable. They ensure that the work done is authentic and meticulous; measurements and angles are definite and look best. A very high degree of accuracy is achieved when the components, lengths, and holes are built highly precisely using these tables. Excellent positioning and definite measurements can be ensured when the pieces are clamped easily to your table.

Conclusion

To achieve high-quality Weldment, you must get as much familiar as possible with your Welding table. Modular fixtures if designed well can ensure consistency, accuracy, precision, safety, and repetitive welds. We hope this article helps you understand how highly beneficial is modular welding table and you invest in them according to your needs. We would be glad to have feedback from our readers. It helps us give better output every time we get connected to our viewers. Keep viewing, keep learning and stay connected with us.