Home » Automatic- CNC Cutting

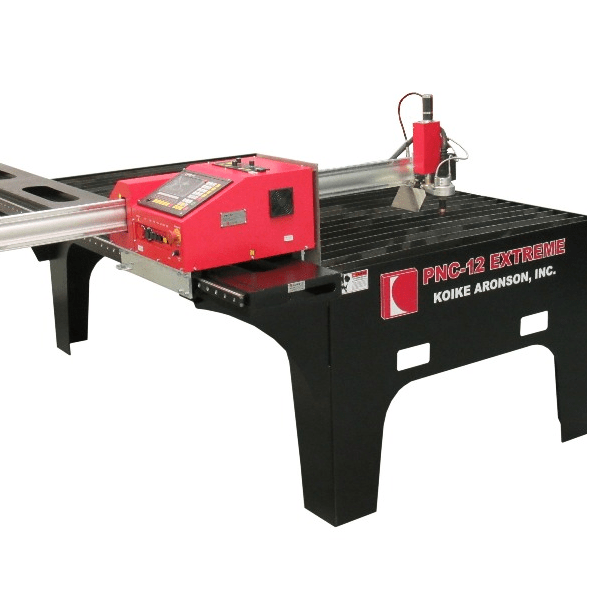

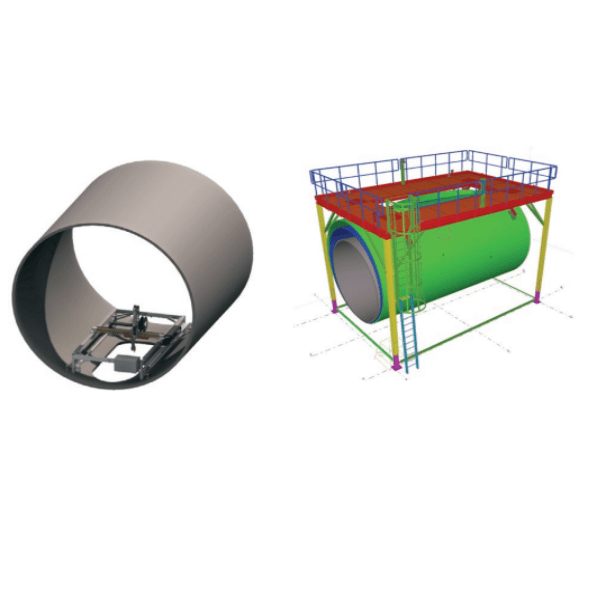

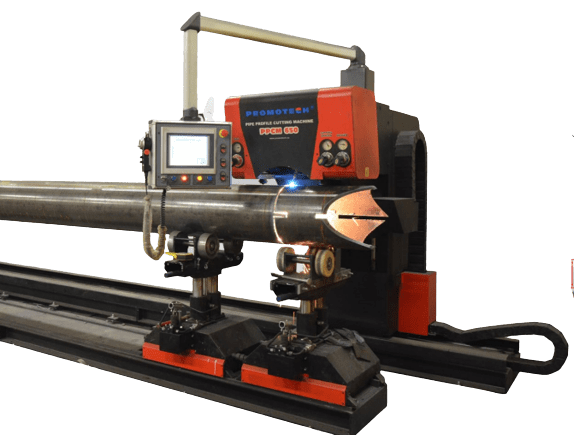

CNC cutting is the most advanced form of metal cutting, almost all industries where continuous metal cutting is part of their manufacturing activity finds a scope of installation of this type of system. The CNC system can take direct drawing input to manipulate cutting head movements to cut the plates or shapes in the desired size as per drawing requirements. The entire process is completely automated with minimum manual intervention.

Frequently integrated cutting processes with this system are Flame, Air Plasma, High Definition Plasma, Laser & Water-Jet to name a few. The system can work with single or multiple cutting torches based on customer production cutting requirements.

We can provide a single-point solution to our customers right from the selection of appropriate system up to implementation and hand holding to the production team.

Our integration partners in this category are Promotech, Koike & ACT to name a few.

Modern Automatic CNC Cutting systems are not limited to one technology – they can incorporate multiple cutting processes based on your production needs. Common integrations include flame cutting, air plasma, high-definition plasma, laser cutting, and water-jet cutting. Each process suits different material types and thicknesses, so the machine can be configured to match the specific application, whether for precision thin cuts or robust thick plate processing.

An automated CNC cutting solution offers several tangible advantages:

Precision and consistency: Every part is cut to the exact specification you define in the digital design.

Higher throughput: Continuous automated operation significantly improves production speed.

Lower dependency on skilled labor: Once programmed, the system runs with minimal supervision.

Reduced waste: Accurate cutting reduces material misuse and rework.

These benefits make CNC cutting ideal for industries where quality, repeatability, and speed matter most.

Choosing the right CNC cutting system depends on several key factors:

Material type and thickness: Different cutting technologies handle specific materials better (e.g., plasma for thicker metal, laser for finer details).

Production volume: High-volume operations benefit from advanced automation features and faster cycles.

Accuracy requirements: Tighter tolerances require machines with higher rigidity and precise controls.

Integration needs: Consider how the system will fit into your existing workflow – automation peripherals like part loaders or nesting software can boost efficiency. Picking the right combination upfront ensures both performance and cost-effectiveness.